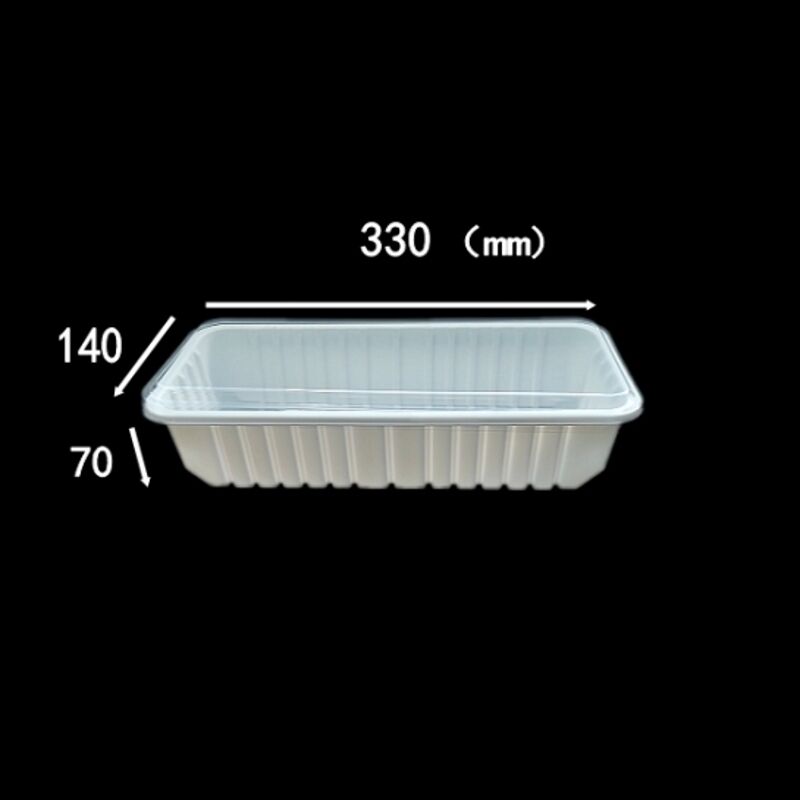

disposable plastic boxes for packing

Disposable plastic boxes for packing represent a versatile and essential solution in modern packaging needs. These containers are engineered using high-grade, food-safe polymers that ensure product integrity while maintaining cost-effectiveness. The boxes feature innovative design elements including snap-fit lids, reinforced corners, and stackable configurations that maximize storage efficiency. Available in various sizes and configurations, these packaging solutions accommodate diverse requirements from food service to retail applications. The manufacturing process employs advanced injection molding technology, resulting in uniform thickness and exceptional durability despite their disposable nature. These boxes typically incorporate clarity-enhanced materials that allow content visibility while protecting against external contaminants. The design includes strategic ribbing patterns that enhance structural stability without compromising on material usage. Modern disposable plastic boxes also feature tamper-evident seals and innovative closure mechanisms that ensure product security during transport and storage. Many variants include compartmentalized designs, making them ideal for organized storage and portion control. The materials used are specifically chosen for their ability to maintain structural integrity across various temperature ranges, making them suitable for both hot and cold storage applications.