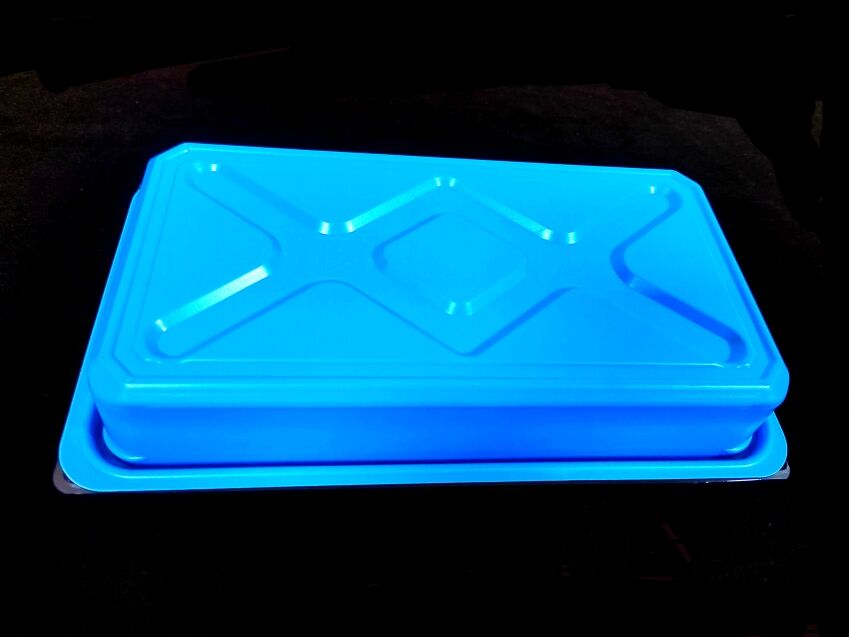

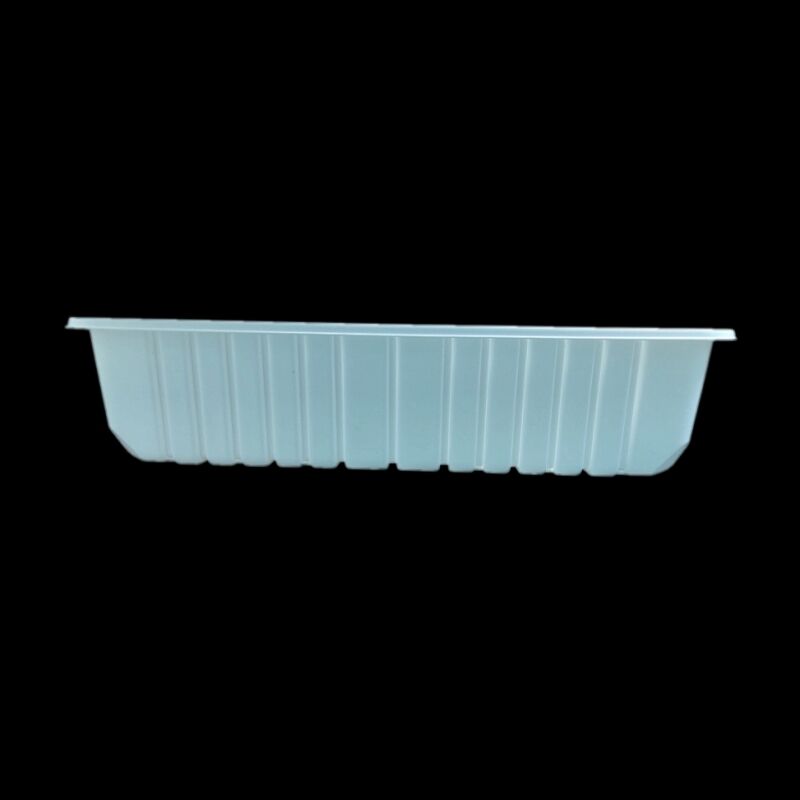

plastic box factory

A plastic box factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality storage and packaging solutions. These facilities utilize advanced injection molding technology and automated production lines to create a diverse range of plastic containers, from small component boxes to large storage units. The factory incorporates precision engineering systems that ensure consistent product quality, with computerized quality control measures monitoring each stage of production. Modern plastic box factories feature sophisticated material handling systems, raw material storage facilities, and efficient assembly lines that can produce thousands of units daily. The manufacturing process begins with carefully selected raw materials, primarily consisting of virgin and recycled plastics, which undergo rigorous testing for durability and safety compliance. The factory's layout typically includes dedicated areas for material preparation, molding operations, quality inspection, packaging, and warehouse storage. Advanced robotics and automation systems handle various tasks, from material feeding to product sorting and packaging, significantly reducing production time while maintaining high precision. These facilities also incorporate energy-efficient systems and waste reduction measures, demonstrating commitment to sustainable manufacturing practices while meeting diverse market demands for plastic storage solutions.