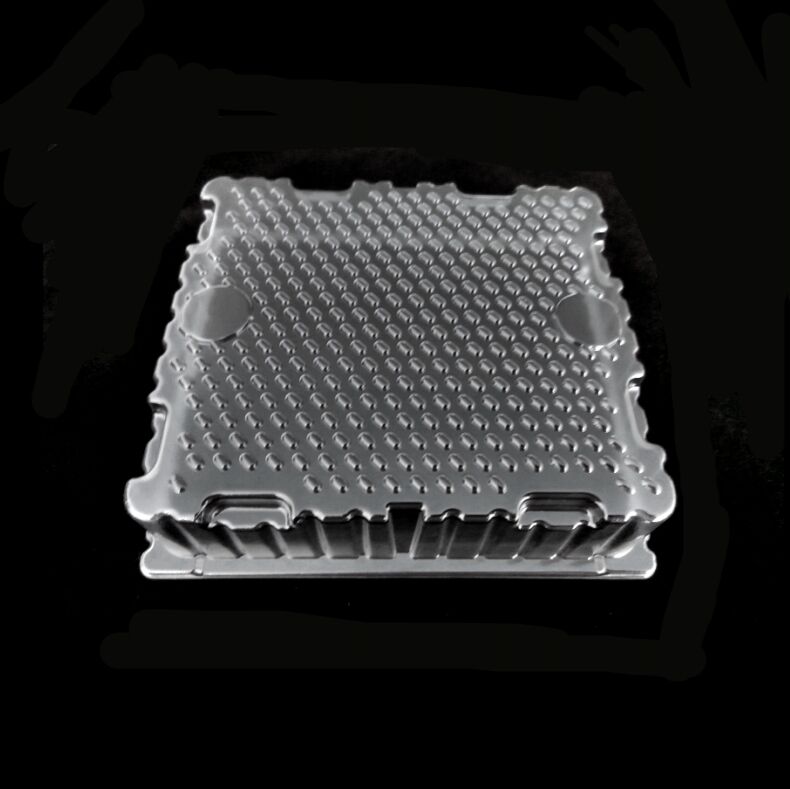

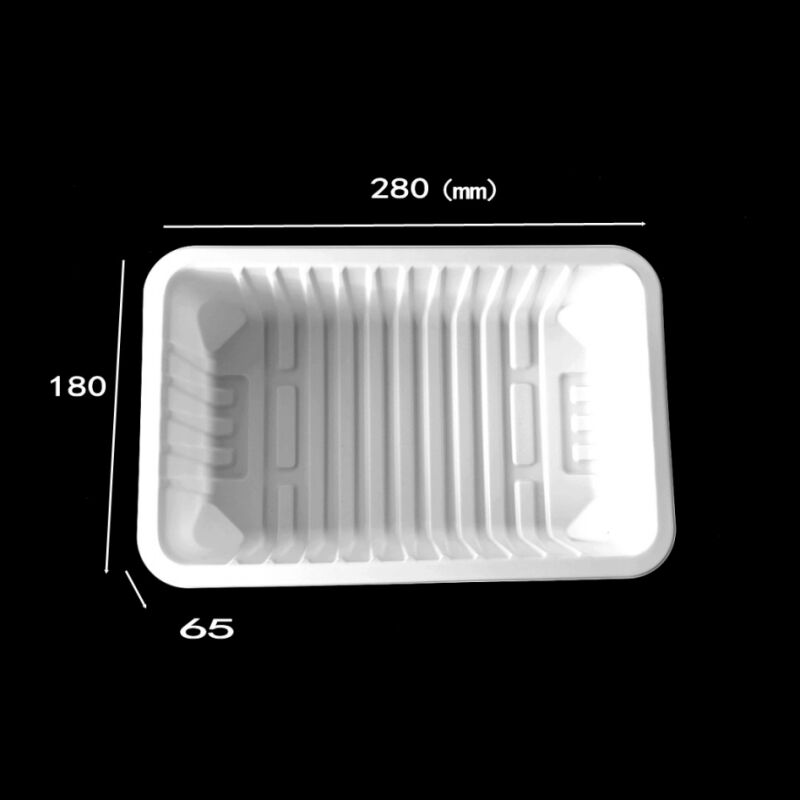

plastic clamshell box made in china

The plastic clamshell box made in China represents a versatile packaging solution that combines durability, transparency, and cost-effectiveness. These containers feature a hinged design that creates two halves connected along one edge, allowing for easy opening and secure closure. Manufactured using high-quality PET or PVC materials, these boxes offer exceptional clarity that showcases the contents while providing robust protection against external factors. The manufacturing process involves advanced thermoforming technology, ensuring consistent quality and precise dimensions. These clamshell boxes come in various sizes and configurations, with customizable compartments to accommodate different products. The design typically includes snap-fit closures or hanging holes for retail display purposes. They are particularly valued in retail packaging, electronic component storage, food packaging, and consumer goods presentation. The boxes undergo strict quality control measures to ensure they meet international safety standards and maintain structural integrity during shipping and handling. Their stackable design optimizes storage space and simplifies inventory management, while the clear material allows for quick visual inspection of contents without opening the package.