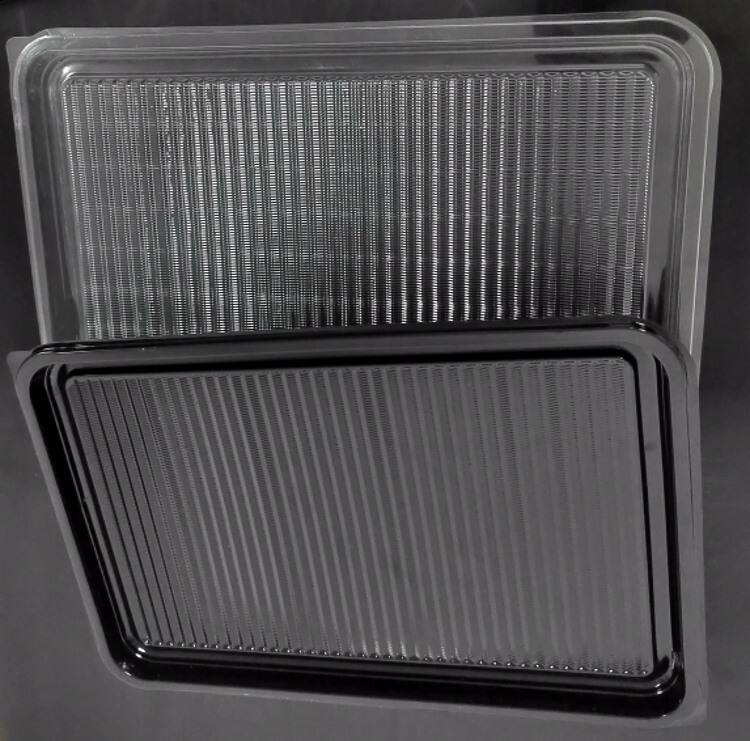

plastic lid factory

A plastic lid factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality closure solutions for various industries. These facilities integrate advanced injection molding systems, automated quality control mechanisms, and precision engineering to create reliable, cost-effective packaging solutions. Modern plastic lid factories employ sophisticated production lines that can simultaneously manufacture multiple lid designs, ranging from simple beverage caps to complex tamper-evident closures. The facilities typically feature clean room environments, ensuring products meet stringent hygiene standards, particularly for food and beverage applications. The manufacturing process incorporates real-time monitoring systems, allowing for immediate adjustments to maintain consistent quality. These factories utilize advanced materials science to develop lids with specific characteristics, such as enhanced durability, temperature resistance, and seal integrity. The production capabilities often include customization options, enabling clients to specify dimensions, colors, and functional features to meet their unique packaging requirements. Quality assurance protocols include rigorous testing for leak prevention, seal integrity, and material consistency, ensuring each product meets industry standards and regulatory requirements.