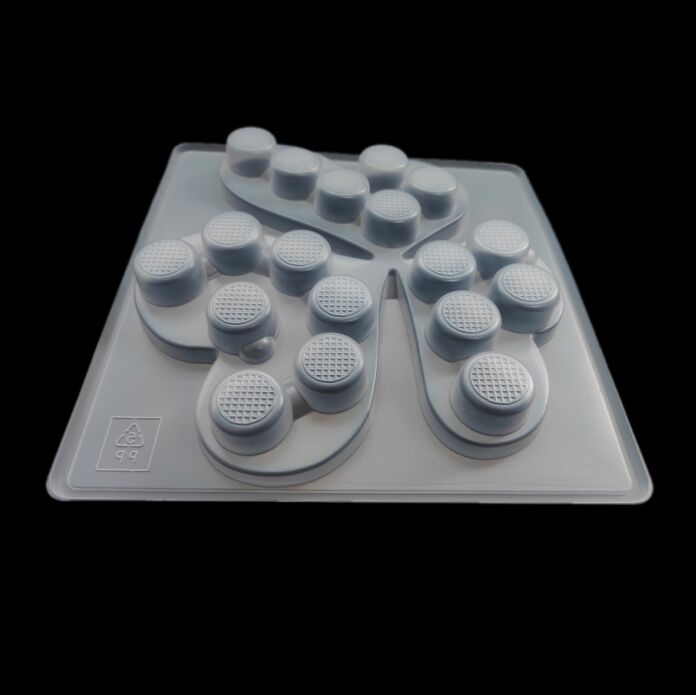

plastic packaging box factory

A plastic packaging box factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality protective containers for various industries. These facilities leverage advanced injection molding and thermoforming technologies to create customizable packaging solutions that meet diverse market demands. The factory's production lines are equipped with precision machinery capable of manufacturing boxes in multiple sizes, shapes, and specifications, ensuring consistent quality and dimensional accuracy. Modern plastic packaging factories incorporate automated systems for material handling, quality control, and inventory management, significantly enhancing production efficiency. They utilize food-grade materials and implement strict quality control measures to meet international safety standards, particularly crucial for food and medical packaging applications. The facility's capabilities extend to various finishing processes, including surface treatments, printing, and assembly operations. Environmental considerations are integrated into the manufacturing process through recycling systems and energy-efficient equipment. The factory maintains research and development departments focused on innovative packaging solutions, material optimization, and sustainable practices. With comprehensive testing facilities, they ensure products meet durability, storage, and transportation requirements. The production setup allows for both high-volume standard products and specialized custom orders, supported by modern mold design and fabrication capabilities.