pp tray factory

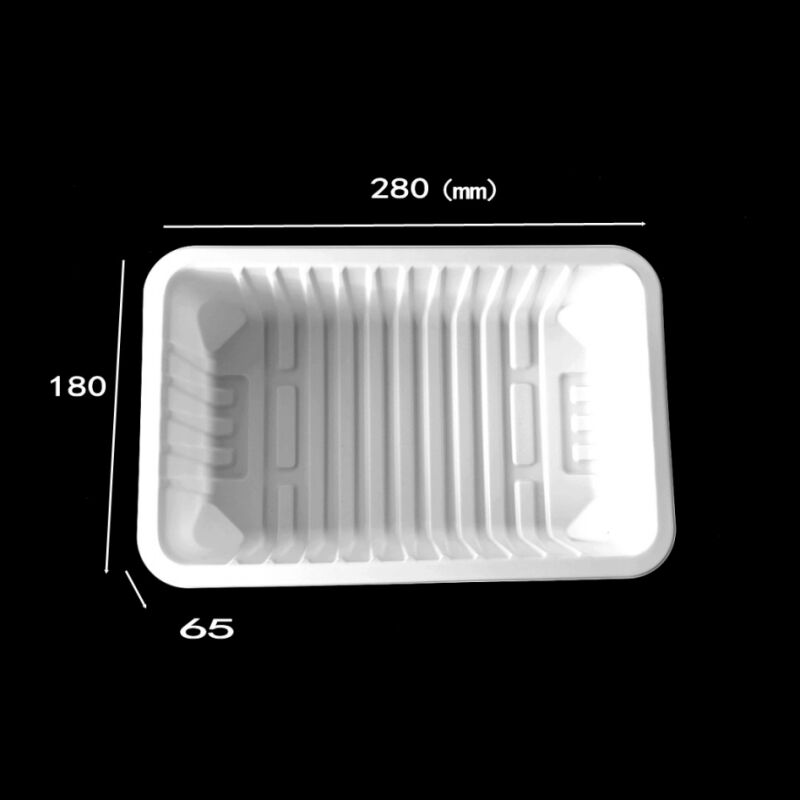

A PP tray factory represents a modern manufacturing facility dedicated to producing high-quality polypropylene trays through advanced injection molding and thermoforming processes. These facilities combine state-of-the-art machinery, automated production lines, and quality control systems to create versatile packaging solutions for various industries. The factory utilizes premium-grade polypropylene materials, ensuring the production of durable, food-safe, and environmentally conscious trays. With sophisticated temperature control systems and precision molding equipment, these facilities maintain consistent product quality while achieving high production efficiency. The manufacturing process incorporates multiple stages, from material preparation and molding to quality inspection and packaging, all monitored by skilled technicians. Advanced robotics and automated handling systems ensure minimal human intervention, reducing contamination risks and maintaining product integrity. The factory's capabilities typically extend to producing various tray designs, sizes, and specifications, catering to diverse customer requirements in food packaging, medical supplies, electronic components, and retail displays.