roll over wrap trays vendors

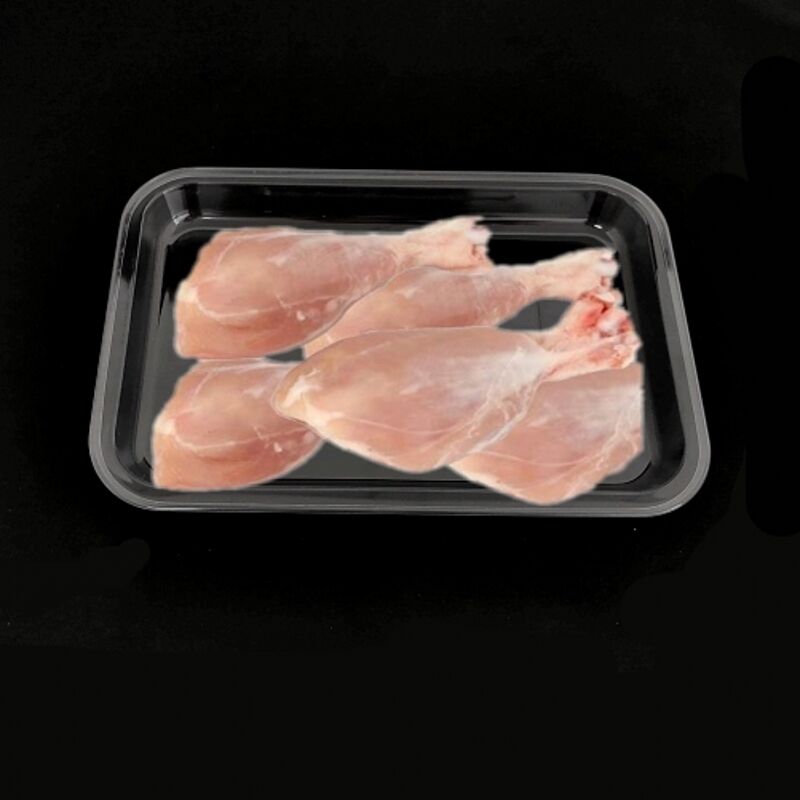

Roll over wrap trays vendors provide essential equipment and solutions for efficient packaging operations in various industries. These vendors specialize in manufacturing and distributing sophisticated tray wrapping systems that automate the packaging process for products requiring secure, attractive presentation. The systems typically feature advanced conveyor mechanisms that smoothly transport products through multiple wrapping stages, ensuring consistent and professional results. Modern roll over wrap tray vendors incorporate cutting-edge technology, including programmable logic controllers (PLCs), touch screen interfaces, and precise tension control systems. These machines can handle various tray sizes and products, from fresh produce to consumer goods, with adjustable wrapping parameters to accommodate different packaging requirements. The equipment often includes features such as automatic film feeding, precise cutting mechanisms, and temperature-controlled sealing systems. Vendors also provide comprehensive support services, including installation, training, and maintenance programs to ensure optimal equipment performance. The systems are designed with efficiency in mind, capable of processing multiple trays per minute while maintaining high quality standards and reducing material waste. Safety features, such as emergency stops and protective guards, are integrated into the design, meeting international safety standards and regulations.