The Evolution of Modern Food Packaging for Dumplings

The way we package and reheat our favorite dumplings has transformed dramatically over the years. Today's microwaveable dumpling packs represent the perfect fusion of convenience and food safety, offering consumers a quick and reliable way to enjoy these beloved Asian delicacies. As manufacturers and consumers become increasingly conscious about packaging materials, the selection process for microwaveable dumpling packs has become more sophisticated, focusing on both functionality and sustainability.

Modern packaging solutions must address multiple concerns: maintaining food freshness, ensuring safe reheating, preventing contamination, and minimizing environmental impact. The materials chosen for microwaveable dumpling packs play a crucial role in meeting these requirements while delivering an optimal dining experience.

Primary Materials for Safe Microwave Heating

Food-Grade Polypropylene Containers

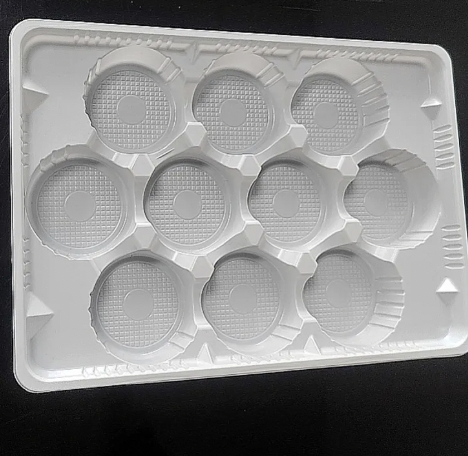

Polypropylene (PP) stands out as a leading choice for microwaveable dumpling packs due to its exceptional heat resistance and food-safe properties. This versatile material maintains structural integrity at high temperatures, typically withstanding heat up to 240°F (116°C). Manufacturers often choose PP for its clarity, allowing consumers to see the product inside while providing excellent moisture barrier properties.

The advantages of polypropylene extend beyond its heat resistance. It's relatively lightweight, cost-effective, and can be easily molded into various shapes and sizes. Modern microwaveable dumpling packs made from PP often feature specially designed steam vents and reinforced corners to enhance the reheating experience.

Crystallized Polyethylene Terephthalate Trays

Crystallized Polyethylene Terephthalate (CPET) represents another excellent option for microwaveable dumpling packs. This material offers superior heat resistance and dimensional stability during microwave heating. CPET trays can withstand temperatures from -40°F to 400°F (-40°C to 204°C), making them suitable for both freezer storage and microwave reheating.

CPET containers maintain their shape without warping or leaching harmful substances into the food. Their dual-ovenable nature means consumers can use either microwave or conventional ovens, providing greater versatility in preparation methods.

Advanced Packaging Technologies

Smart Steam Release Systems

Modern microwaveable dumpling packs incorporate sophisticated steam release mechanisms. These systems typically utilize specialized films or valve technologies that allow controlled steam release during heating. This prevents excessive pressure buildup while maintaining optimal moisture levels, ensuring dumplings heat evenly and retain their desired texture.

The latest innovations in steam release technology include self-venting films that automatically create small openings at specific temperatures. This eliminates the need for consumers to manually puncture the packaging, providing a more convenient and consistent heating experience.

Multi-Layer Barrier Materials

Advanced microwaveable dumpling packs often feature multi-layer construction, combining different materials to achieve optimal performance. These layers typically include moisture barriers, oxygen barriers, and heat-resistant materials. The strategic combination helps preserve dumpling freshness while ensuring safe and effective microwave heating.

Each layer serves a specific purpose, from preventing moisture loss to maintaining structural integrity during heating. The outer layer often provides durability and printing surfaces, while inner layers focus on food contact safety and heat management.

Sustainable Packaging Solutions

Bio-Based Alternatives

The industry is witnessing a significant shift toward sustainable materials for microwaveable dumpling packs. Bio-based polymers derived from renewable resources offer promising alternatives to traditional petroleum-based plastics. These materials maintain similar heat resistance and safety properties while reducing environmental impact.

Some manufacturers have successfully developed microwaveable containers using modified cellulose, cornstarch-based materials, and other plant-derived substances. These eco-friendly options decompose more readily than conventional plastics while meeting food safety and heating requirements.

Recyclable Components

Modern packaging designs increasingly emphasize recyclability without compromising performance. New generations of microwaveable dumpling packs feature easily separable components, allowing consumers to recycle different materials appropriately. Clear recycling instructions and material identification symbols help facilitate proper disposal.

Some manufacturers have introduced mono-material solutions, using a single type of plastic throughout the package to simplify recycling. These innovations demonstrate the industry's commitment to environmental responsibility while maintaining product quality and safety.

Safety Considerations and Standards

Material Testing Requirements

All materials used in microwaveable dumpling packs must undergo rigorous testing to ensure safety during microwave heating. This includes evaluation of chemical migration, heat resistance, and potential interactions with food components. Manufacturers must comply with FDA regulations and similar international standards regarding food-contact materials.

Testing protocols typically examine material behavior under various heating conditions, including extended microwave exposure and temperature cycling. This ensures packaging maintains its integrity and safety throughout the product's shelf life and during preparation.

Quality Control Measures

The production of microwaveable dumpling packs involves strict quality control procedures to maintain consistent performance and safety. This includes regular testing of material properties, seal integrity, and microwave heating behavior. Manufacturers implement comprehensive monitoring systems to detect any deviations from established standards.

Quality assurance programs often incorporate real-time testing and documentation of key parameters, ensuring each batch of packaging meets specified requirements for food safety and microwave compatibility.

Frequently Asked Questions

Can all plastic containers be used for microwaving dumplings?

Not all plastic containers are suitable for microwave use. Only containers specifically labeled as microwave-safe should be used. Look for materials like polypropylene (PP) or crystallized polyethylene terephthalate (CPET) that are designed to withstand microwave heating temperatures without melting or releasing harmful chemicals.

How long do microwaveable dumpling packs maintain food freshness?

The shelf life of dumplings in microwaveable packs typically ranges from 6-12 months when stored in proper freezer conditions. This duration depends on the packaging material quality, storage temperature, and barrier properties of the container. Always check the expiration date printed on the package.

Are eco-friendly microwaveable dumpling packs as effective as traditional ones?

Modern eco-friendly packaging options have been developed to match or exceed the performance of traditional materials. While maintaining food safety and heating efficiency, sustainable alternatives often provide additional benefits like better biodegradability and reduced environmental impact. Their effectiveness in microwave heating is thoroughly tested before market release.