rullkantet kjøttbaker til salgs

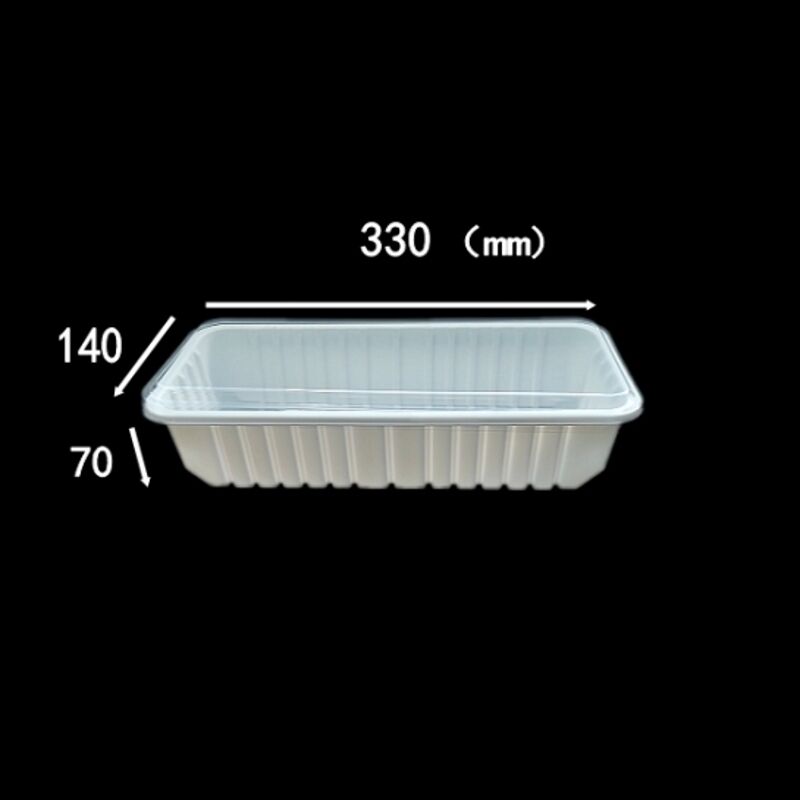

Trayen med rullet kant for kjøtt representerer en betydelig fremgang i matpakkingsteknologien, spesifikt utviklet for å møte de kravende kravene til lagring og visning av kjøtt. Denne innovasjonstrayen har en nøyaktig utformet konstruksjon med rullet kant som gir økt strukturell integritet og forhindre skarpe kanter, sørger for sikker håndtering gjennom hele forsyningskjeden. Trayens design inkluderer avansert polymer teknologi som opprettholder optimal friskhet samtidig som den tillater fremragende produkt synlighet. Med sin romslige innsiden og strategisk utformet dybde akkommoderer trayen ulike typer kjøttkutter mens den minimerer produktbevegelse under transport. Materialekomposisjonen sørger for kompatibilitet med bransjens standard overwrap maskiner og varmeleseutstyr, forenkler pakkeoperasjoner. Disse trayene lages under strikte kvalitetskontrollforhold, oppfyller FDA's fødevarekrav og internasjonale sikkerhetsstandarder. Designet inkluderer også strategiske avledningskanaler som hjelper med å opprettholde kjøttkvalitet ved å forhindre unnødige væskeakkumulering, dermed utvide holdbarhet og opprettholde produktets utseende. Tilgjengelig i flere størrelser og dybder er disse trayene versatilt nok til å håndtere alt fra premium stekkar til hakkekjøttprodukter, gjør dem til en nødvendig komponent i moderne kjøttretail operasjoner.