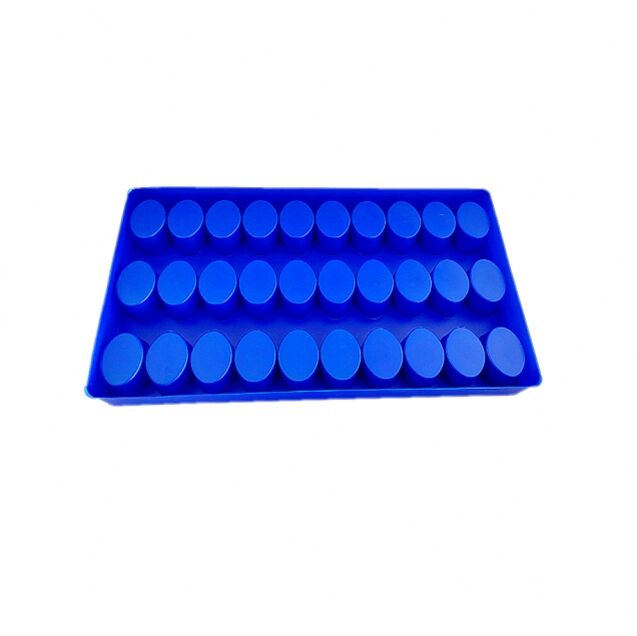

blister plastic packaging types

Blister plastic packaging represents a versatile and sophisticated solution in modern packaging technology. This packaging type consists of a pre-formed plastic cavity, typically made from PVC, PET, or similar materials, matched with a backing of paperboard, aluminum, or plastic. The design creates a transparent, protective enclosure that securely holds products while allowing visibility. The manufacturing process involves thermoforming, where plastic sheets are heated and molded into specific shapes using dedicated tooling. These packages come in various configurations, including clamshell, face-seal, card-backed, and trap blisters. Each type serves specific purposes, from consumer goods protection to medical device sterility maintenance. The technology behind blister packaging has evolved to include advanced features such as child-resistant designs, tamper-evident seals, and sustainable material options. Applications span across pharmaceuticals, consumer electronics, toys, hardware, and personal care products. The packaging's ability to provide product protection while offering excellent display capabilities makes it particularly valuable in retail environments. Modern blister packaging also incorporates anti-static properties, moisture barriers, and UV protection, ensuring product integrity throughout the supply chain.