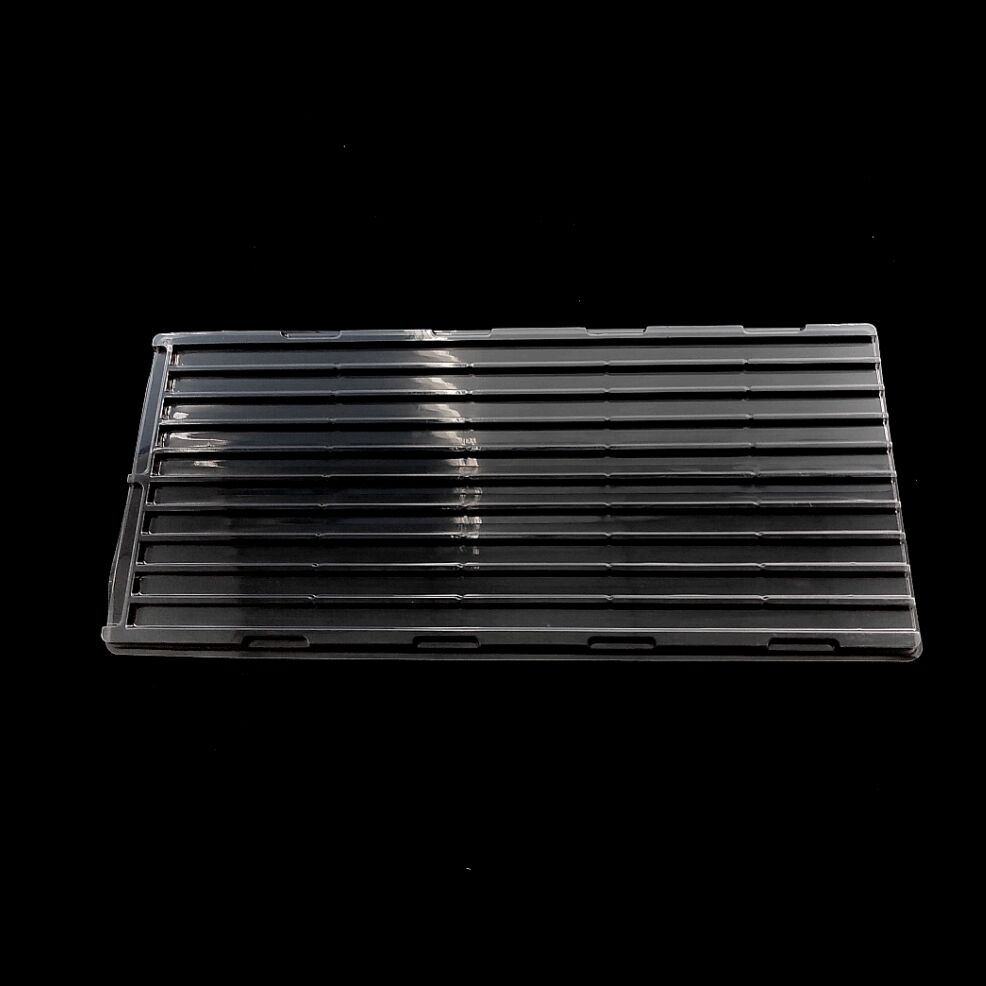

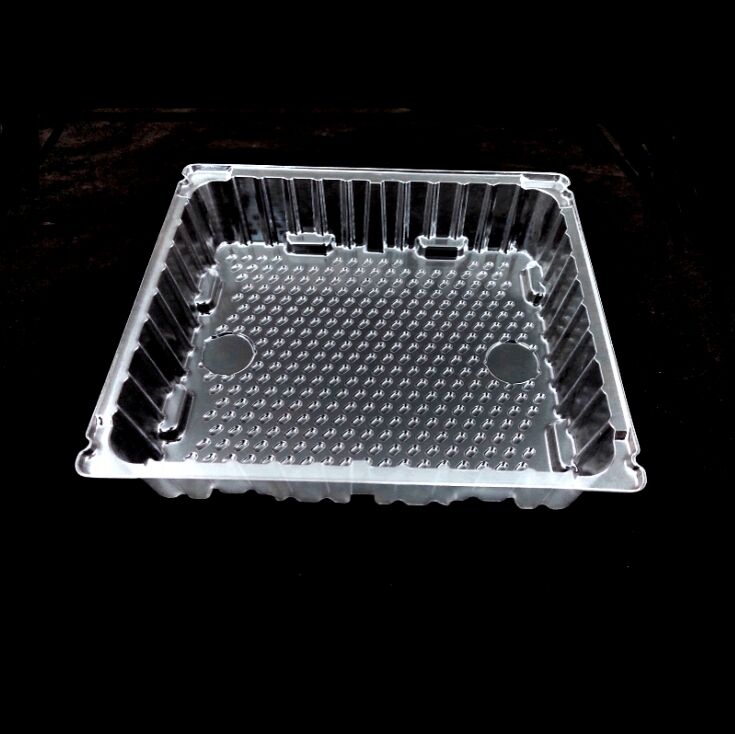

blister vacuum form tray factory

A blister vacuum form tray factory represents a cutting-edge manufacturing facility dedicated to producing high-quality packaging solutions through advanced thermoforming processes. These specialized facilities utilize state-of-the-art machinery and precision engineering to create custom-designed plastic trays that perfectly accommodate various products. The manufacturing process involves heating plastic sheets to a specific temperature, then using vacuum pressure to form them over precise molds, resulting in perfectly contoured packaging solutions. The factory employs sophisticated quality control systems, ensuring each tray meets exact specifications and industry standards. Advanced automation systems streamline production, enabling high-volume output while maintaining consistent quality. The facility's capabilities extend to producing trays in various sizes, shapes, and materials, catering to diverse industries including electronics, medical devices, consumer goods, and food packaging. Modern blister vacuum form tray factories incorporate sustainable practices, utilizing recyclable materials and implementing energy-efficient production methods. They also feature clean room environments for specialized medical and electronic packaging production, ensuring compliance with industry regulations and standards.