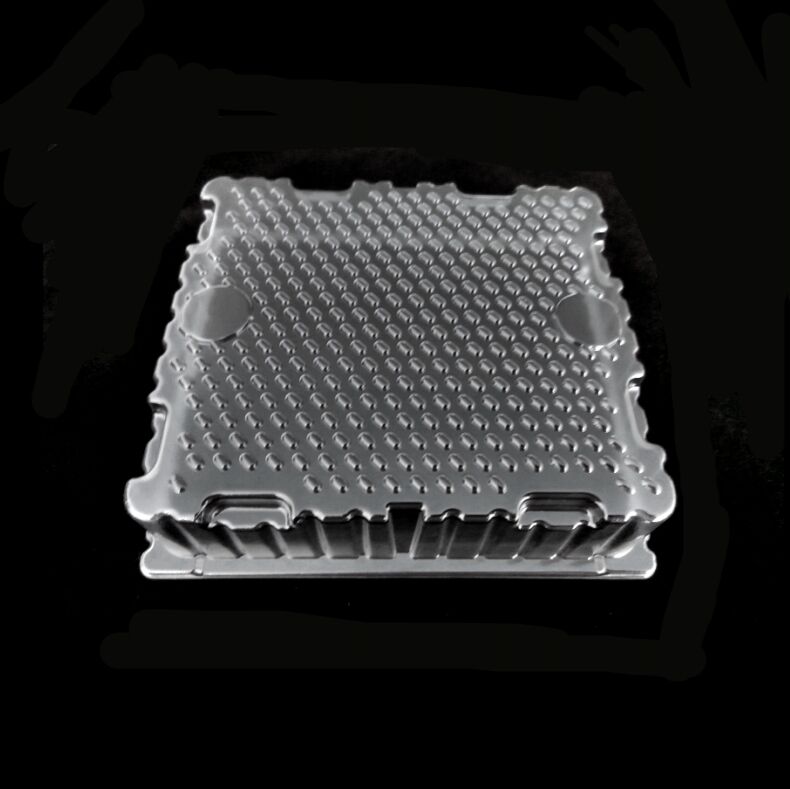

blister vacuum form tray made in china

The blister vacuum form tray made in China represents a cutting-edge packaging solution that combines precision engineering with cost-effective manufacturing. These trays are produced through a sophisticated thermoforming process where plastic sheets are heated to a pliable forming temperature, stretched onto a mold, and then cooled to create a rigid, custom-shaped container. The manufacturing process employs advanced vacuum forming technology, ensuring consistent quality and dimensional accuracy. These trays feature carefully designed cavities that securely hold products, preventing movement and potential damage during transportation and storage. The materials used typically include PET, PVC, or PS, all selected for their excellent clarity, durability, and recyclability. Chinese manufacturers implement strict quality control measures throughout the production process, ensuring each tray meets international standards while maintaining competitive pricing. The trays' design can be customized to accommodate various product sizes and shapes, making them ideal for electronics, medical devices, cosmetics, and consumer goods packaging. Advanced surface treatments can be applied to enhance the trays' protective properties and aesthetic appeal.