plastic cover factory

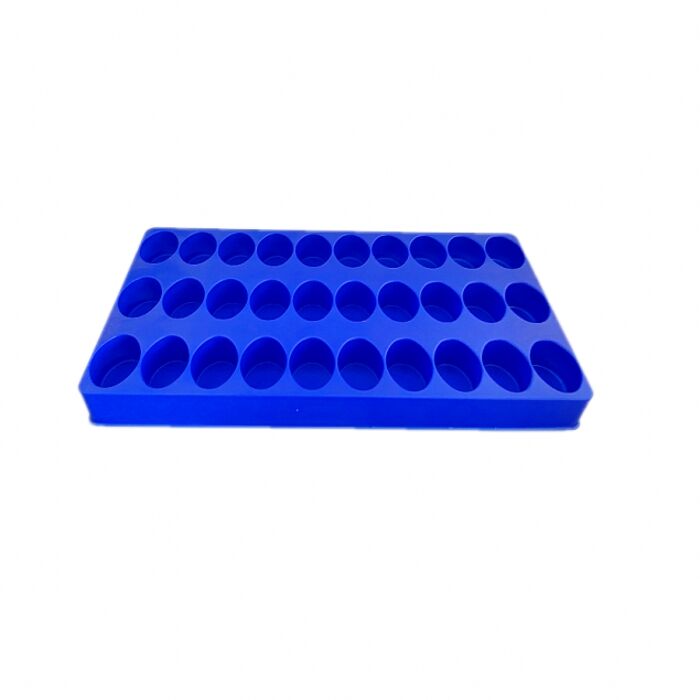

A plastic cover factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality protective covers and enclosures for various applications. These facilities utilize advanced injection molding technology, precision engineering, and automated production lines to create durable, customizable plastic covers that meet diverse industry requirements. The factory incorporates modern quality control systems, ensuring each product meets stringent standards for durability, dimensional accuracy, and finish quality. The manufacturing process begins with carefully selected raw materials, primarily engineering-grade polymers, which undergo extensive testing before entering production. Advanced CAD/CAM systems enable precise design implementation, while sophisticated molding machines operate at optimal efficiency to produce consistent, high-quality results. The facility maintains specialized areas for material preparation, molding, finishing, and quality inspection, ensuring a streamlined production flow. Environmental control systems regulate temperature and humidity levels, crucial for maintaining product quality and manufacturing precision. The factory's capabilities extend to producing covers ranging from small electronic device enclosures to large industrial protective covers, with the flexibility to accommodate custom specifications and varying production volumes.