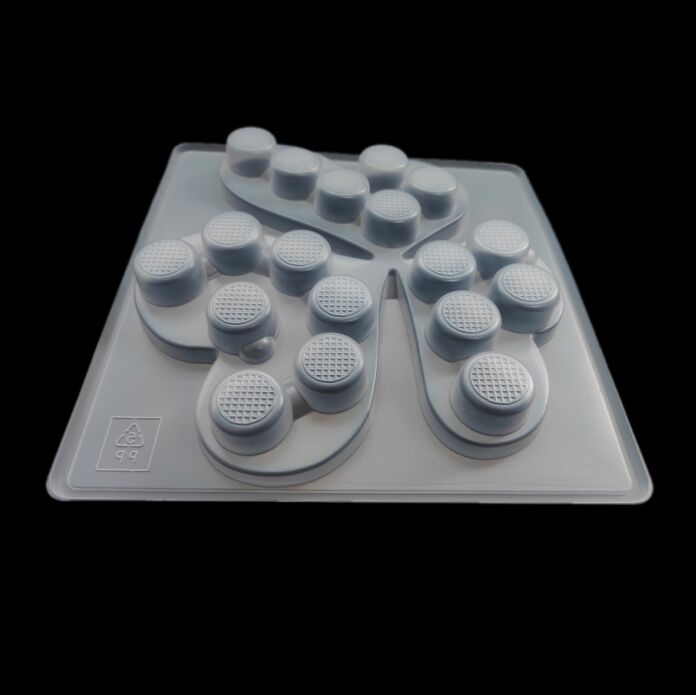

plastic cover types

Plastic covers represent a versatile and essential component in various industries and applications, offering protection and functionality across multiple scenarios. These covers come in diverse types, including injection-molded covers, thermoformed covers, and vacuum-formed covers, each engineered to meet specific requirements. The primary function of plastic covers is to provide protective enclosure while maintaining accessibility and functionality. Advanced manufacturing processes ensure precise dimensional accuracy and consistent quality, incorporating features such as weather resistance, UV protection, and impact resistance. Modern plastic covers often integrate innovative design elements such as snap-fit assemblies, reinforced edges, and custom mounting solutions. They can be produced in various materials, from basic polyethylene to high-performance engineering plastics, each selected based on specific application requirements. These covers often feature ergonomic designs that facilitate easy installation and removal while maintaining secure attachment during use. Many variants include specialized features such as EMI shielding for electronic applications, thermal management capabilities for temperature-sensitive components, and chemical resistance for industrial environments. The versatility of plastic covers extends to their finish options, including textured surfaces, transparent sections, and custom color matching to align with branding requirements.