plastic cover manufacturer

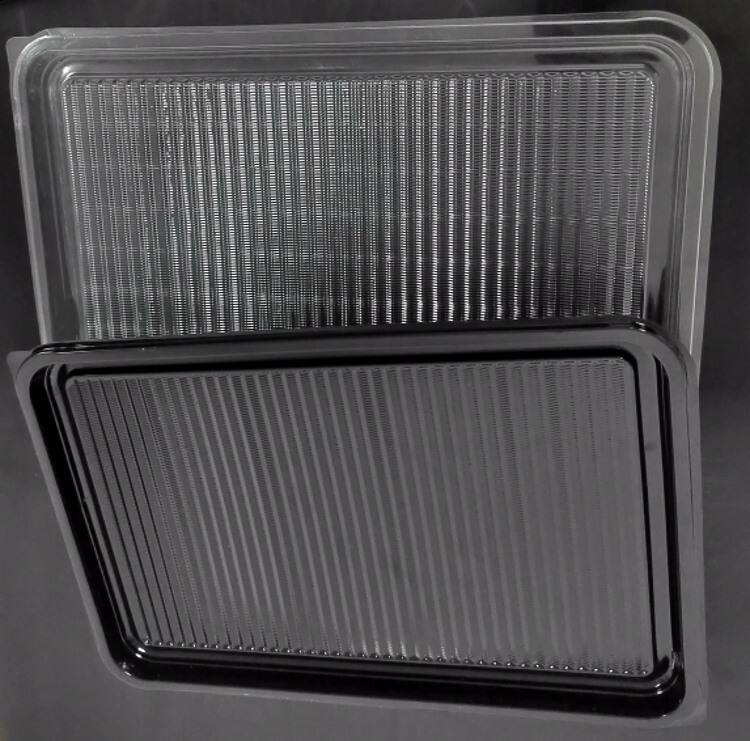

A plastic cover manufacturer specializes in designing and producing high-quality protective enclosures for various industrial and consumer applications. These facilities employ state-of-the-art injection molding technology, enabling the creation of precise, durable covers that meet diverse specifications. The manufacturing process incorporates advanced quality control systems, ensuring each product maintains consistent standards while adhering to international safety regulations. Modern plastic cover manufacturers utilize automated production lines equipped with precision machinery, capable of producing both standard and custom-designed covers in various sizes, thicknesses, and materials. These facilities often implement sustainable practices, including recycling programs and energy-efficient manufacturing processes. The production capabilities extend to various plastic types, including ABS, polycarbonate, and polyethylene, each selected based on specific application requirements. These manufacturers offer comprehensive services, from initial design consultation to final product delivery, incorporating computer-aided design (CAD) systems for accurate prototyping and testing. Quality assurance protocols include rigorous testing for impact resistance, weather durability, and chemical compatibility, ensuring products meet or exceed industry standards. The manufacturing facilities maintain clean room environments when necessary, particularly for covers designed for sensitive electronic components or medical devices.