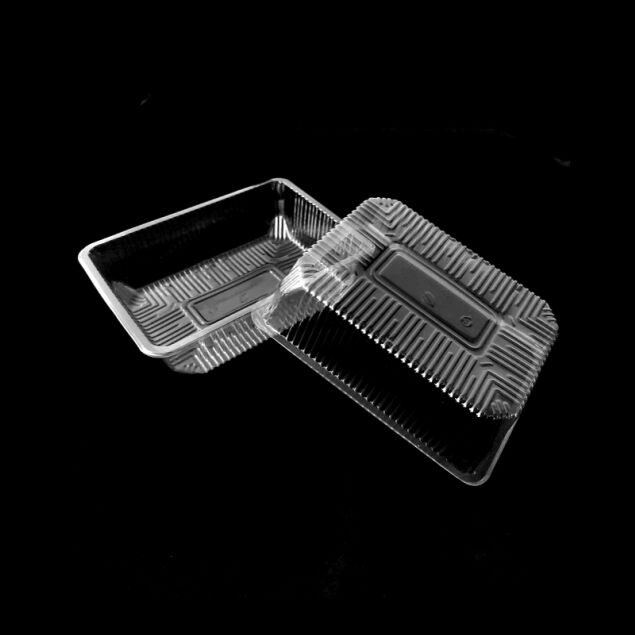

plastic meat tray factory

A plastic meat tray factory represents a modern manufacturing facility dedicated to producing high-quality food packaging solutions. These facilities employ advanced thermoforming technology and automated production lines to create durable, hygienic meat trays that meet strict food safety standards. The factory incorporates state-of-the-art equipment for material processing, molding, quality control, and packaging operations. Key features include precision thermoforming machines that shape food-grade plastic materials into various tray designs, automated cutting systems for consistent sizing, and quality inspection stations utilizing computer vision technology. The facility maintains stringent cleanliness protocols and implements comprehensive quality management systems to ensure product safety and reliability. Modern plastic meat tray factories also emphasize sustainability through efficient material usage, recycling programs, and energy-saving manufacturing processes. They typically feature specialized areas for raw material storage, production, quality testing, and finished product warehousing. The factory's operations are supported by advanced logistics systems, enabling efficient order processing and delivery scheduling. These facilities often maintain research and development departments focused on innovative packaging solutions and improved manufacturing techniques.