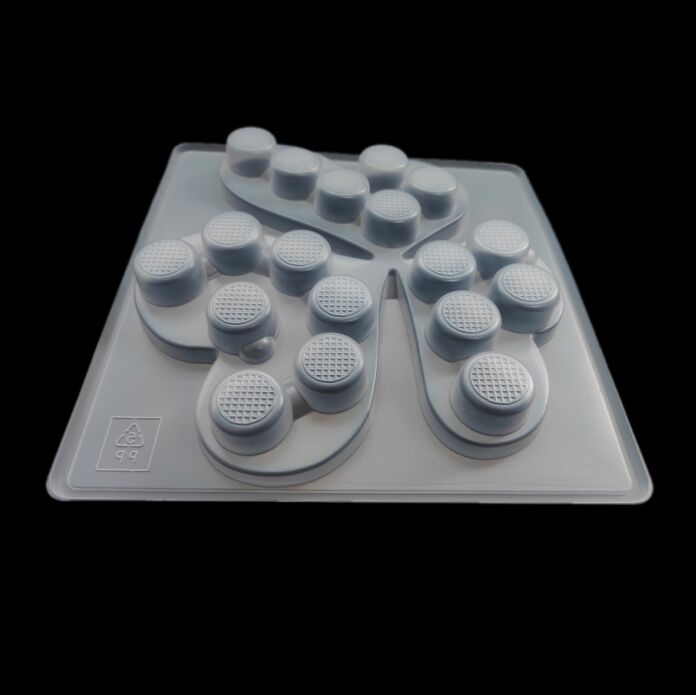

white plastic meat trays

White plastic meat trays are essential packaging solutions designed specifically for the food industry, particularly for meat products. These trays are manufactured using food-grade polystyrene or similar FDA-approved materials, ensuring safe food contact and storage. The trays feature a bright white color that enhances product presentation and includes a carefully engineered design with raised edges to contain liquids and prevent leakage. Their construction typically incorporates special absorbent properties to manage meat juices and maintain product freshness. The trays come in various sizes and depths to accommodate different cuts of meat and portion sizes, from individual servings to family packs. They are designed with stability in mind, featuring a flat bottom and reinforced corners that prevent deformation during handling and storage. The material used is specifically chosen for its ability to withstand both refrigeration and freezing temperatures without becoming brittle or changing shape. Additionally, these trays are compatible with common packaging methods including stretch film wrapping and modified atmosphere packaging, making them versatile for different retail environments. The surface texture is optimized to prevent meat from sticking while facilitating easy product removal by consumers.