types of blister packs

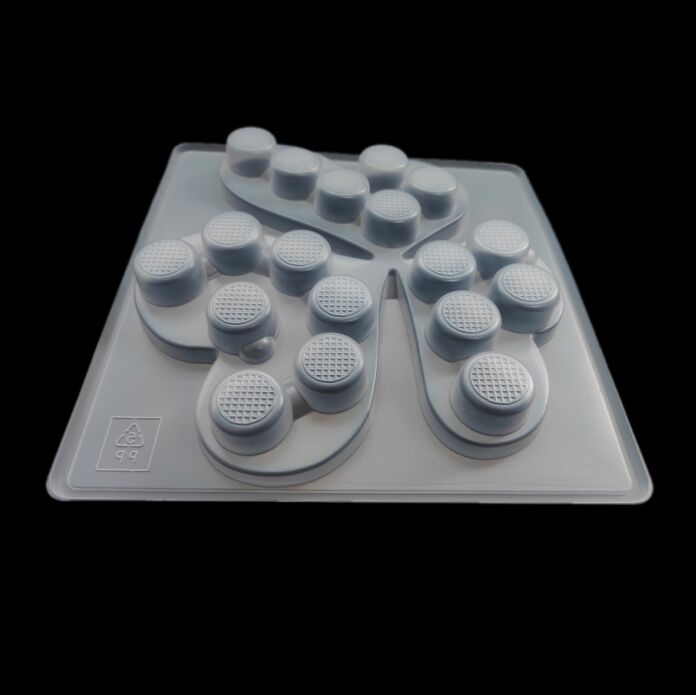

Blister packs represent a versatile packaging solution that comes in several distinct types, each designed to meet specific product protection and presentation needs. The main types include thermoformed blister packs, cold-formed blister packs, and clamshell blisters. Thermoformed blisters utilize heat-moldable plastic materials, typically PVC or PET, shaped into precise cavities through heat and pressure. Cold-formed blisters, commonly made from aluminum foil, are formed without heat and offer superior barrier properties. Clamshell blisters feature a hinged design that folds over itself, creating a secure enclosure. These packaging solutions incorporate various technical features, including child-resistant mechanisms, tamper-evident seals, and moisture barriers. The applications span across pharmaceutical, consumer goods, food, and electronics industries. Each type offers specific advantages in terms of product visibility, protection, and shelf presentation. The manufacturing process involves precise tooling and quality control measures to ensure consistent cavity formation and seal integrity. Modern blister packs also incorporate smart packaging elements, such as QR codes and anti-counterfeiting features, enhancing their functionality beyond basic protection.