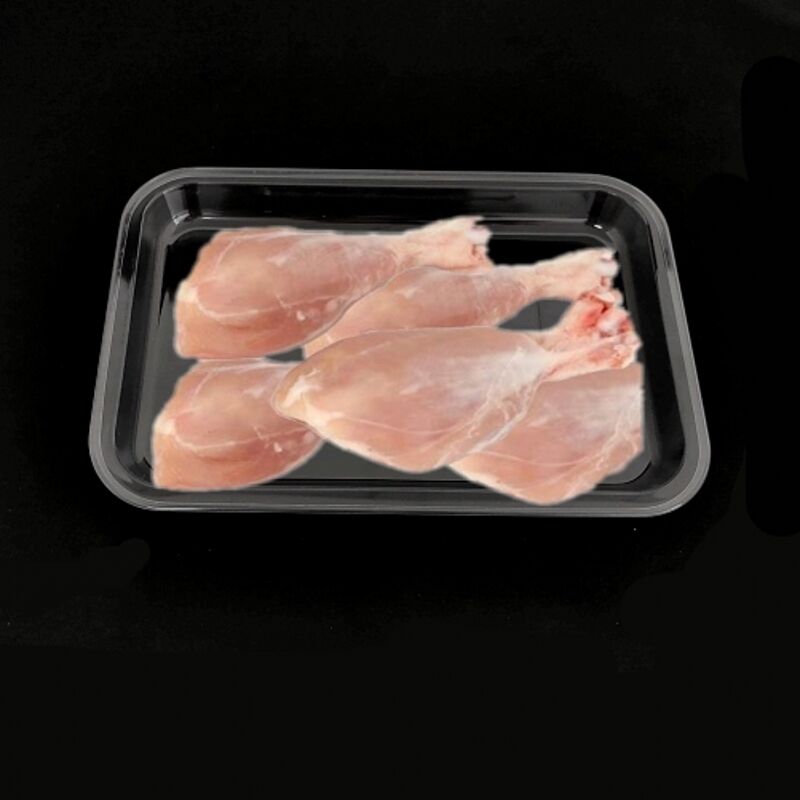

пластмасови блистер упаковки за продажба

Продажбата на пластмасови блистърни упаковки представлява многострунно и ефикасно решение за защита и показване на продукти. Това иновативно решение за упаковка се състои от предформирана пластмасова каверна или джобче, обикновено направена от PVC, PET или подобни материали, което се запечатва към карта-основа или друг слой пластмаса. Упаковката е проектирана да защитава продуктите, като одновременно ги представя чрез прозрачната си повърхност, което я прави идеална за ритейлно показване. Процесът на производство включва термоформиране, при което пластмасовите листове се затоплят и формират в специфични форми, за да се адаптират към различните размери и конфигурации на продуктите. Тези упаковки предлагат изключителна прочност, осигурявайки надпреваряваща защита срещу физическо повредяване, влажност и замърсяване. Дизайнът позволява персонализация по отношение на размер, форма и цвят, което я прави подходяща за широк спектър от индустрии, включително фармацевтика, електроника, играчки и потребителски стоки. Модерните блистърни упаковки включват напреднали системи за сигурност, като печати, които показват ако е била разтревожена, и конструкции, трудни за деца, особено важни за фармацевтични приложения. Упаковката също предлагат отлична способност за настъпване и ефективно използване на полочното пространство, което я прави предпочитан избор за търговци и дистрибутори. Благодарение на комбинацията от защита на продукта, vizualna привлекателност и prakticheska функционалност, блистърната пластмасова упаковка продължава да бъде водещо решение в индустрията.