custom blister packaging

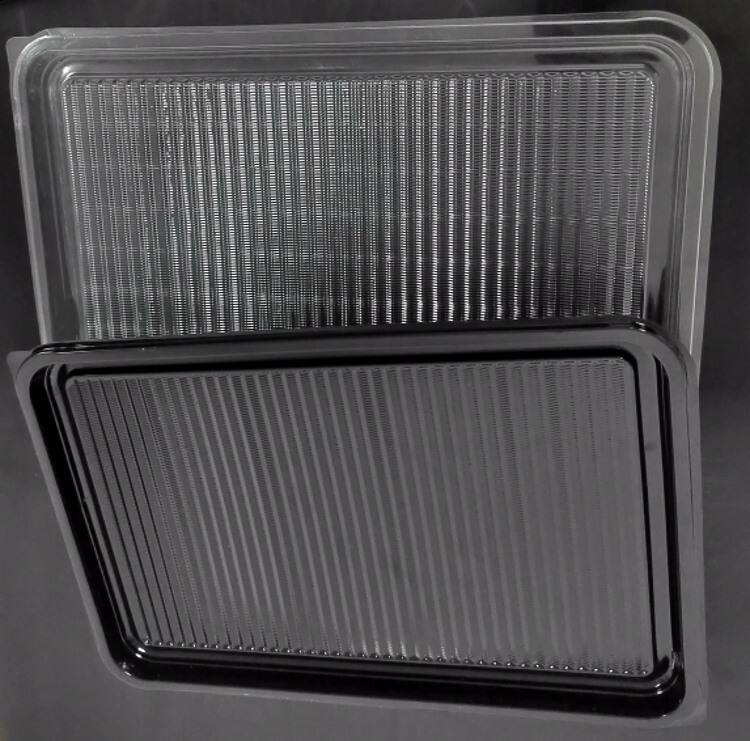

Custom blister packaging represents a sophisticated solution in modern packaging technology, combining functionality with aesthetic appeal. This versatile packaging method involves forming a cavity or pocket from plastic material, precisely shaped to accommodate specific products while providing clear visibility and protection. The manufacturing process utilizes advanced thermoforming techniques, where plastic sheets are heated and molded into custom shapes that perfectly contour to the product dimensions. These packages typically consist of two main components: a formed plastic cavity and a backing material, which can be card, foil, or additional plastic. The technology incorporates various thickness options and material selections, including PVC, PET, and PETG, each offering distinct characteristics suitable for different applications. Custom blister packaging excels in retail environments, pharmaceutical applications, consumer electronics, and various industrial sectors. The transparent nature of the packaging allows for immediate product visualization while maintaining structural integrity and protection against external factors. Modern manufacturing capabilities enable the integration of security features, such as tamper-evident seals and anti-counterfeiting measures, making it particularly valuable for sensitive products. The design flexibility allows for hanging holes, easy-open features, and custom branding elements, enhancing both functionality and marketing potential.