blister pack suppliers

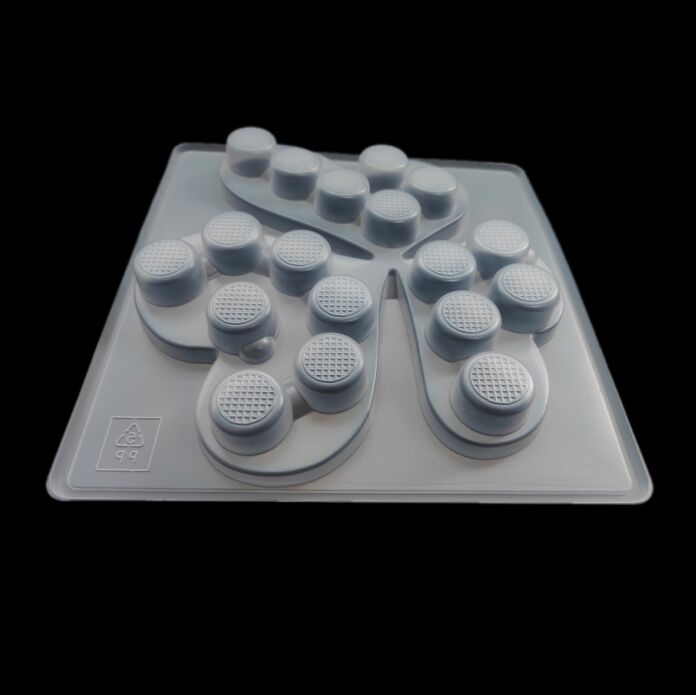

Blister pack suppliers play a crucial role in modern packaging solutions, offering comprehensive services for pharmaceutical, consumer goods, and industrial sectors. These specialized companies provide cutting-edge blister packaging equipment, materials, and expertise to ensure products are safely contained and attractively presented. Their operations typically encompass the design and manufacture of custom blister packaging solutions, utilizing advanced thermoforming technology and quality control systems. Modern blister pack suppliers integrate automated production lines capable of handling various materials, including PVC, PVDC, and aluminum foil, while maintaining strict adherence to international quality standards and regulatory requirements. They offer flexible manufacturing capabilities, from small batch productions to high-volume runs, supported by advanced CAD/CAM systems for precise tooling and design optimization. These suppliers also provide valuable consulting services, helping clients select the most appropriate materials and designs for their specific product requirements, while considering factors such as moisture protection, tamper evidence, and child resistance. Their comprehensive quality management systems ensure consistent product quality, with regular testing and validation procedures to maintain packaging integrity and stability.