plastic food tray factory

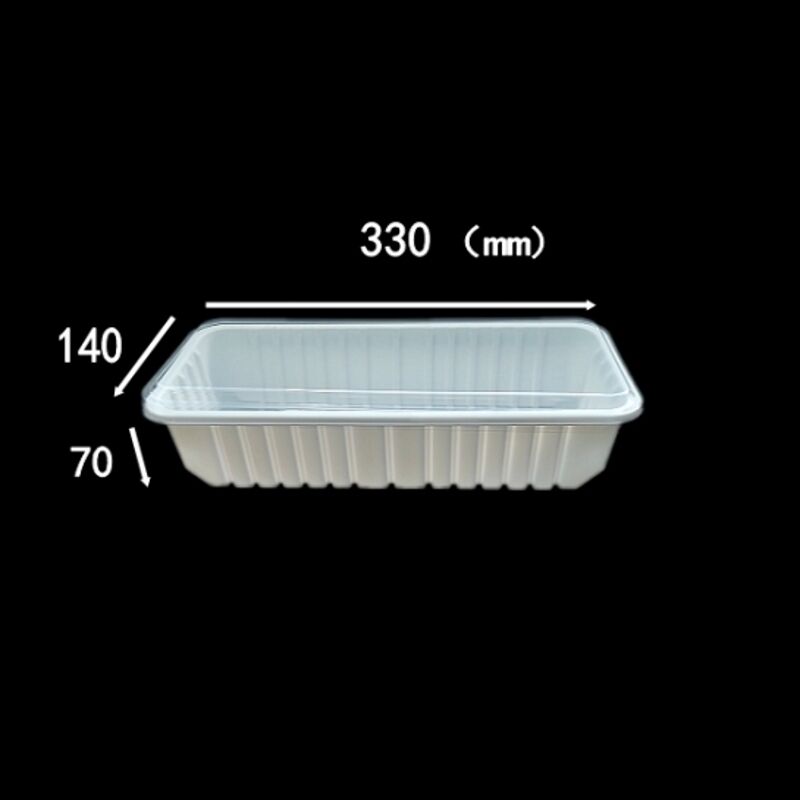

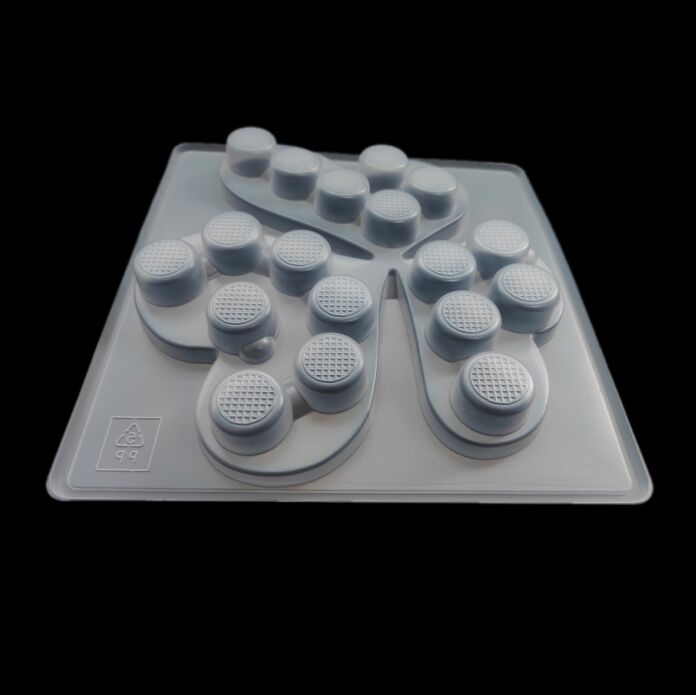

A plastic food tray factory represents a modern manufacturing facility dedicated to producing high-quality food packaging solutions. These facilities utilize advanced injection molding and thermoforming technologies to create versatile food trays that meet strict industry standards. The production process involves sophisticated automation systems that ensure consistent quality and high output efficiency. State-of-the-art machinery handles everything from raw material processing to final product inspection, maintaining precise temperature control and pressure parameters throughout the manufacturing cycle. The factory incorporates clean room environments for hygienic production, meeting FDA and international food safety standards. Quality control systems employ computer-aided testing equipment to verify product specifications, structural integrity, and food-safe properties. The facility's production lines are capable of manufacturing various tray sizes and designs, from single-compartment to multi-compartment configurations, catering to diverse food service needs. Advanced materials selection processes ensure the use of food-grade plastics that are both durable and environmentally responsible. The factory also features automated packaging systems and inventory management solutions that streamline the distribution process.