plastic food tray price

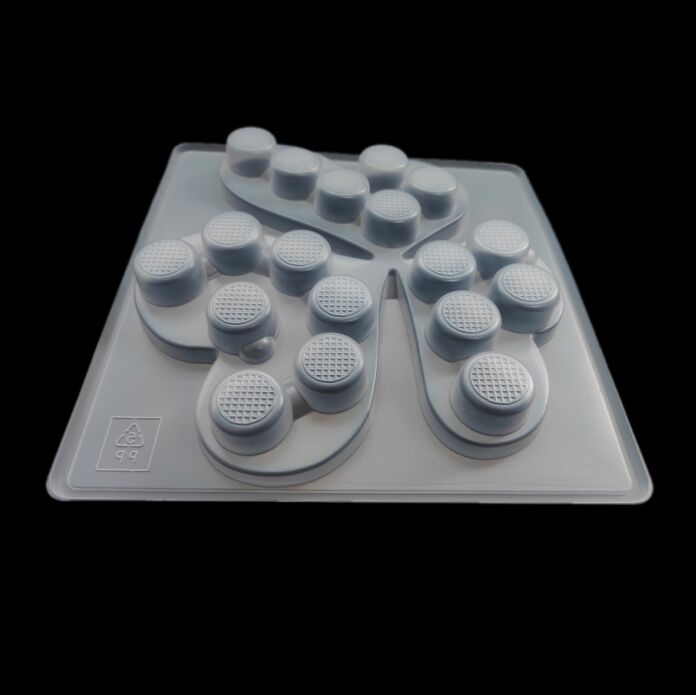

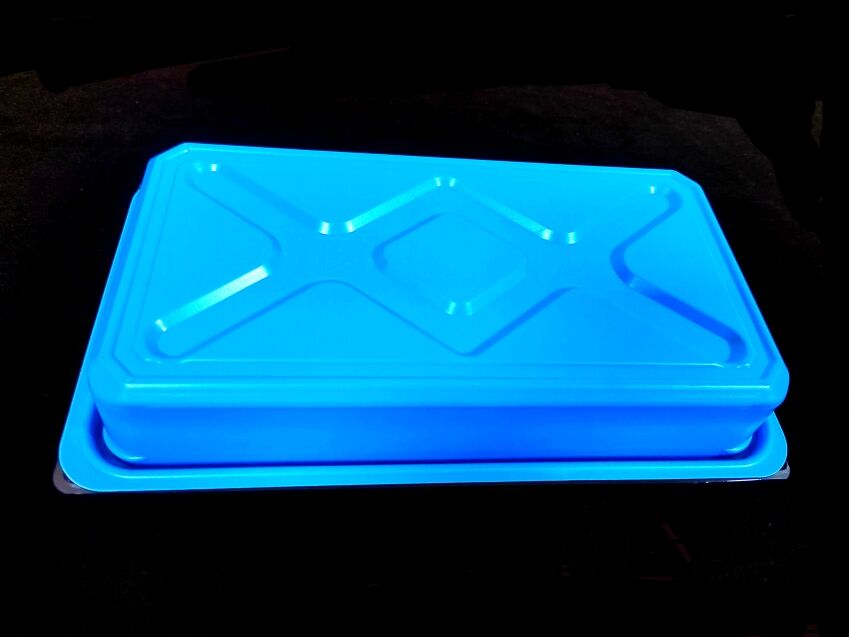

Plastic food tray pricing encompasses various factors that influence the final cost of these essential food packaging solutions. These trays, manufactured from food-grade plastics, offer versatile storage and serving options for both commercial and residential use. The price points vary depending on material quality, size specifications, production volume, and additional features such as compartmentalization or special coatings. Modern manufacturing techniques, including injection molding and thermoforming, allow for cost-effective production while maintaining high quality standards. The pricing structure typically reflects bulk purchase options, with significant cost savings available for larger orders. Material options range from basic polypropylene to premium PET materials, each affecting the final price point. Technological advancements in production processes have led to more competitive pricing while improving durability and functionality. These trays often feature design elements like stackability, moisture resistance, and temperature tolerance, all of which factor into the pricing matrix. Additionally, customization options such as brand logos, specific dimensions, or color choices may influence the overall cost.