blister vacuum form tray price

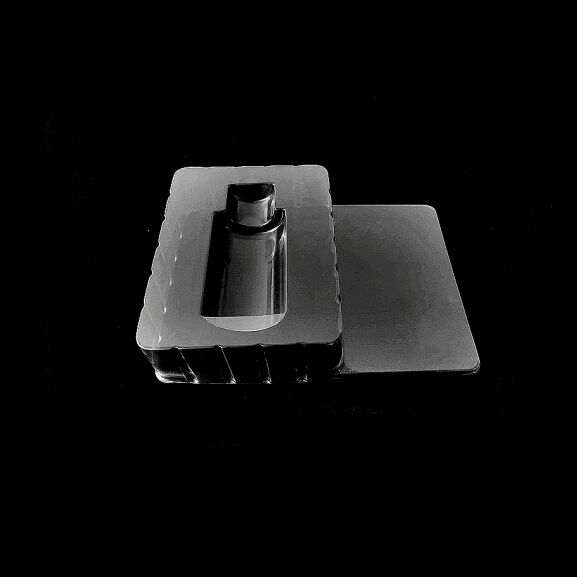

The blister vacuum form tray price represents a crucial consideration in modern packaging solutions, offering a cost-effective approach to product presentation and protection. These trays, manufactured through a sophisticated vacuum forming process, combine durability with aesthetic appeal while maintaining competitive pricing structures. The pricing typically varies based on factors such as material thickness, complexity of design, production volume, and customization requirements. Standard configurations generally range from basic single-cavity designs to complex multi-cavity arrangements, each affecting the final cost. The manufacturing process involves heating plastic sheets to a pliable state, then using vacuum pressure to form them against a mold, creating precise, uniform trays. This technology enables manufacturers to produce high-quality packaging solutions while maintaining reasonable price points that benefit both producers and end-users. The cost efficiency of blister vacuum form trays is particularly evident in their ability to reduce material waste, optimize storage space, and provide excellent product visibility while ensuring protection.