blister vacuum form tray vendors

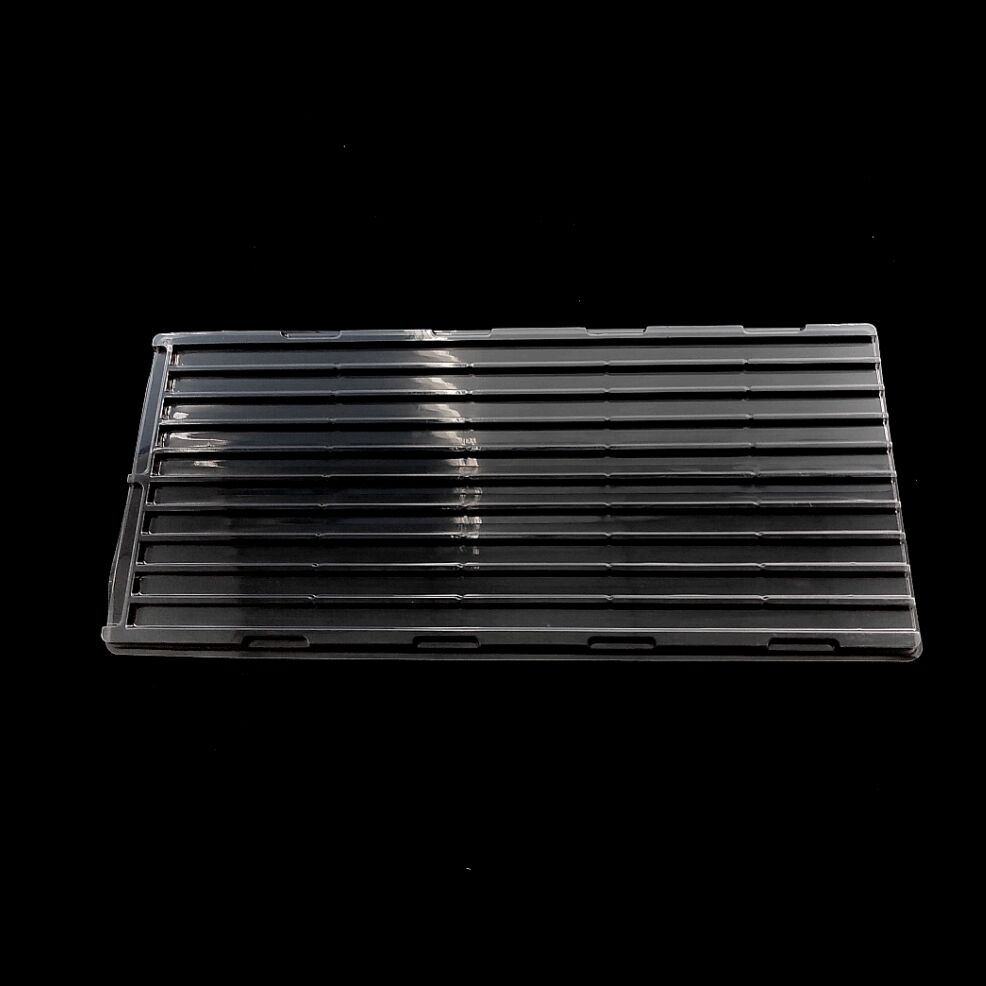

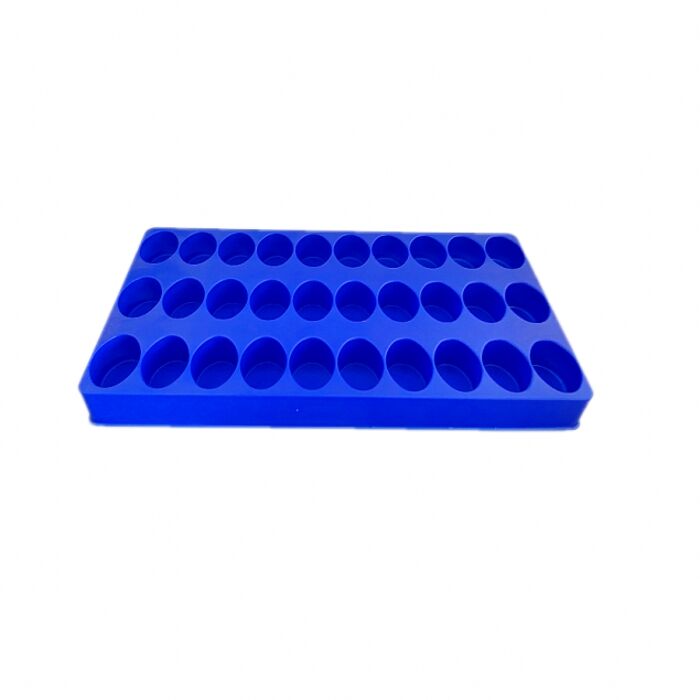

Blister vacuum form tray vendors are specialized manufacturers and suppliers who provide essential packaging solutions for various industries. These vendors utilize advanced thermoforming technology to create custom-designed plastic trays that securely hold products through a combination of heat and vacuum pressure. The process involves heating plastic sheets to a precise temperature, then using vacuum pressure to form them around specific molds. These vendors typically offer comprehensive services, from initial design consultation to final production, ensuring that each tray meets exact specifications for product protection, presentation, and functionality. Modern blister vacuum form tray vendors employ sophisticated equipment capable of producing trays with consistent quality, precise dimensions, and various material options, including PET, PVC, and biodegradable alternatives. They serve diverse sectors including pharmaceutical, electronics, consumer goods, and medical device industries, providing solutions that meet regulatory requirements and industry standards. The vendors often incorporate advanced quality control systems, automated production lines, and sustainable manufacturing practices to deliver cost-effective, reliable packaging solutions that enhance product visibility and protection while optimizing storage and transportation efficiency.