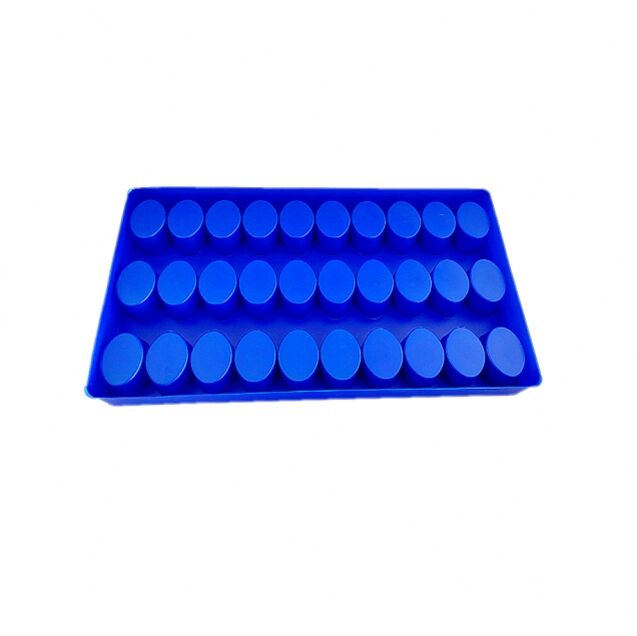

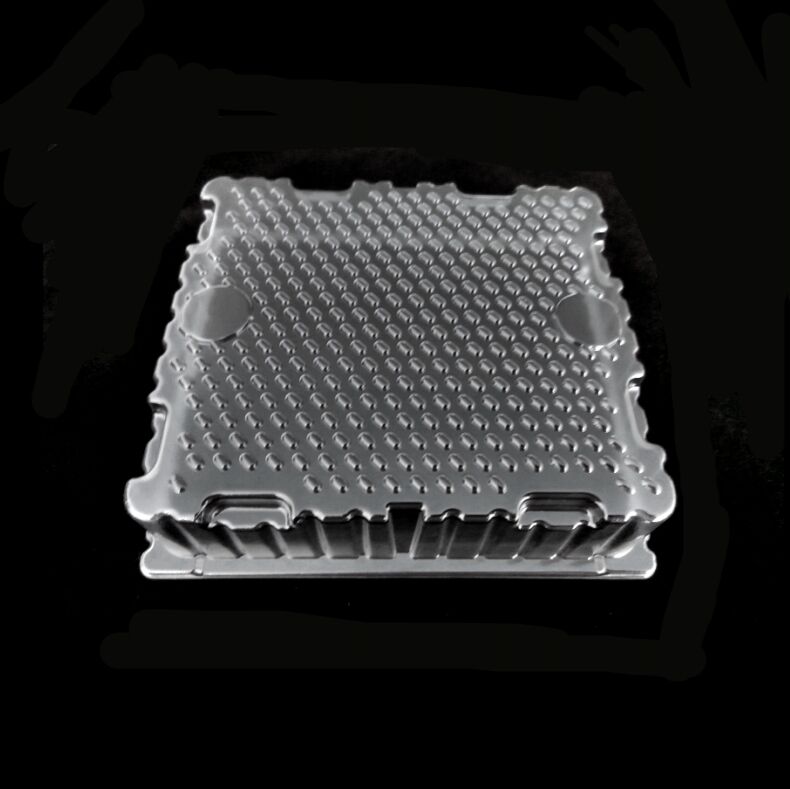

blister vacuum form tray manufacturer

A blister vacuum form tray manufacturer specializes in producing high-quality packaging solutions through advanced thermoforming technology. These sophisticated systems utilize precise temperature control and vacuum forming processes to create custom-designed trays that perfectly accommodate various products. The manufacturing process involves heating specialized plastic sheets to their optimal forming temperature, then using vacuum pressure to mold them into precise shapes. These machines incorporate cutting-edge features including programmable heating zones, accurate pressure control systems, and automated material handling capabilities. The manufacturer's equipment can process various thermoplastic materials, including PVC, PET, and PETG, offering flexibility in material selection based on specific application requirements. The production line typically includes pre-heating stations, forming stations, and automated cutting systems, ensuring consistent quality and high production efficiency. These systems can produce trays with various depths, shapes, and sizes, making them ideal for medical devices, consumer electronics, food packaging, and industrial components. The manufacturing process adheres to strict quality control standards, incorporating real-time monitoring systems and automated inspection protocols to maintain product consistency. Advanced tooling systems allow for quick changeovers between different tray designs, maximizing production flexibility and efficiency. The manufacturer's expertise extends to custom design services, helping clients develop optimal packaging solutions for their specific needs while ensuring cost-effectiveness and sustainability.