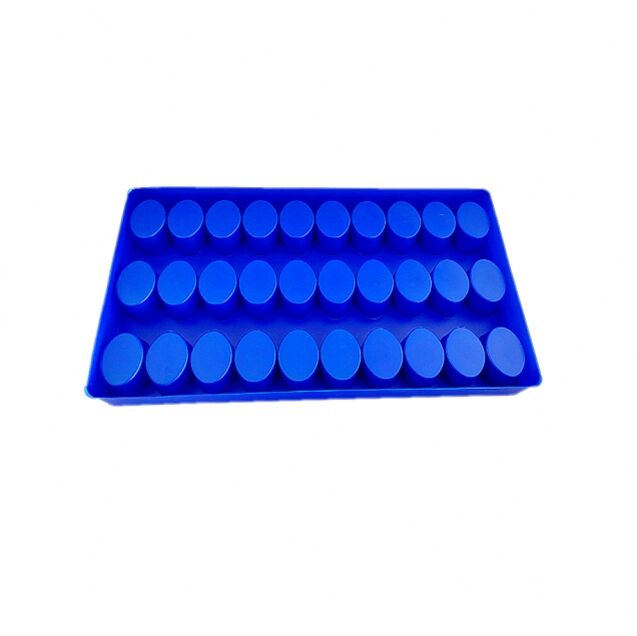

blister vacuum form tray

The blister vacuum form tray represents a cutting-edge packaging solution that combines precision engineering with practical functionality. This innovative packaging component utilizes advanced thermoforming technology to create custom-fitted compartments that securely hold products in place. The manufacturing process involves heating specialized plastic sheets to a precise temperature before applying vacuum pressure to form the desired shape and contours. These trays feature carefully designed cavities that conform to product dimensions, ensuring optimal protection during storage and transportation. The material composition typically includes high-grade, food-safe plastics that offer excellent clarity and durability. What sets the blister vacuum form tray apart is its versatility in accommodating various product sizes and shapes, making it ideal for industries ranging from electronics and medical devices to consumer goods and retail merchandise. The precision-engineered design incorporates features such as reinforced corners, smooth edges, and strategic support structures that enhance both protection and presentation. Moreover, these trays often include anti-static properties and moisture barriers, crucial for sensitive electronic components and medical supplies. The manufacturing process allows for seamless integration with automated packaging lines, improving efficiency and reducing labor costs.