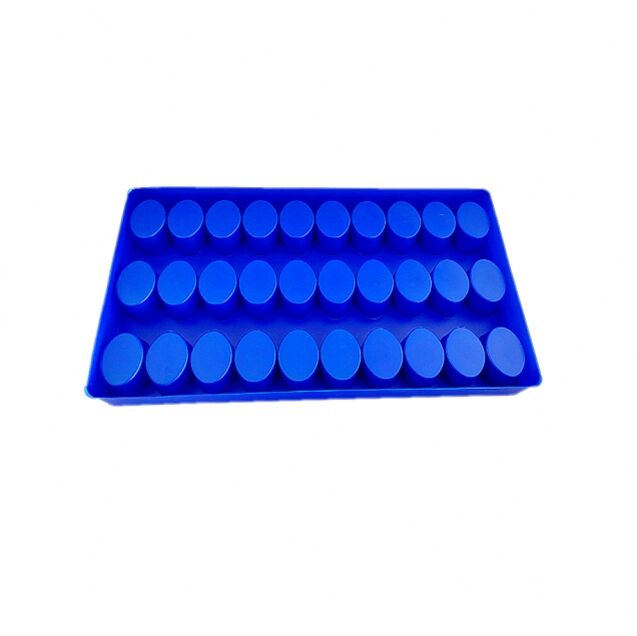

Food Safety and Quality Preservation Features

These plastic trays incorporate multiple features specifically designed to maintain food safety and quality throughout the storage period. The material composition is FDA-approved and completely free of harmful chemicals, ensuring no leaching occurs even during extended storage periods. The surface texture is engineered to minimize ice crystal formation, which helps preserve food texture and taste. Specialized barrier properties prevent moisture migration and oxygen penetration, effectively reducing the risk of freezer burn and maintaining food freshness. The trays feature a hermetic seal design that, when used with appropriate lidding materials, creates an airtight environment that extends shelf life. The smooth interior surfaces prevent food particles from adhering, facilitating complete food removal and easy cleaning. Advanced antimicrobial properties are incorporated into some variants, providing an additional layer of food safety protection.