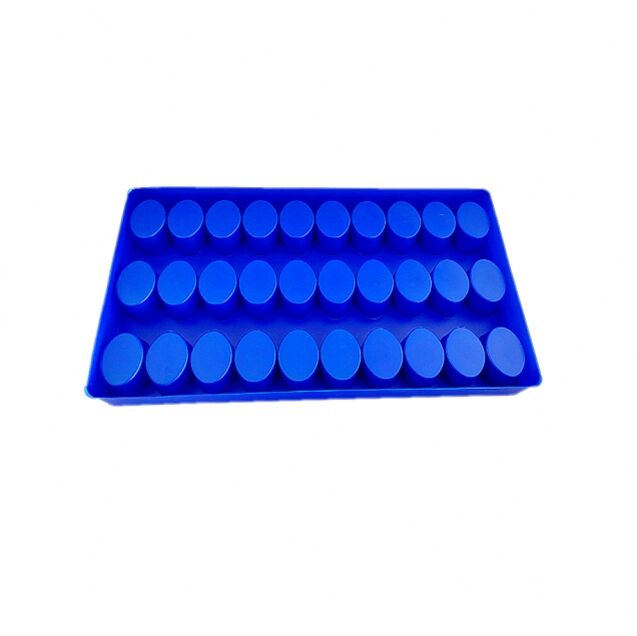

plastic trays for frozen food

Plastic trays for frozen food represent an essential component in modern food packaging and preservation systems. These specialized containers are engineered to withstand extreme temperature variations while maintaining structural integrity and food safety. Manufactured from food-grade polymers, these trays feature innovative designs that accommodate various portion sizes and food types, from ready-made meals to raw ingredients. The trays incorporate advanced barrier properties that prevent moisture loss and freezer burn, ensuring food quality remains optimal throughout the storage period. Their construction typically includes reinforced corners and edges to prevent cracking under frozen conditions, while the surface texture is optimized to prevent food from sticking. Many designs feature compartmentalized sections, allowing for portion control and separation of different food components. The materials used are specifically chosen for their ability to maintain flexibility at sub-zero temperatures, preventing brittleness and breakage. These trays often include features like stackability for efficient storage and tamper-evident seals for food safety. They are compatible with various sealing technologies, including heat sealing and modified atmosphere packaging, extending shelf life and maintaining food freshness.