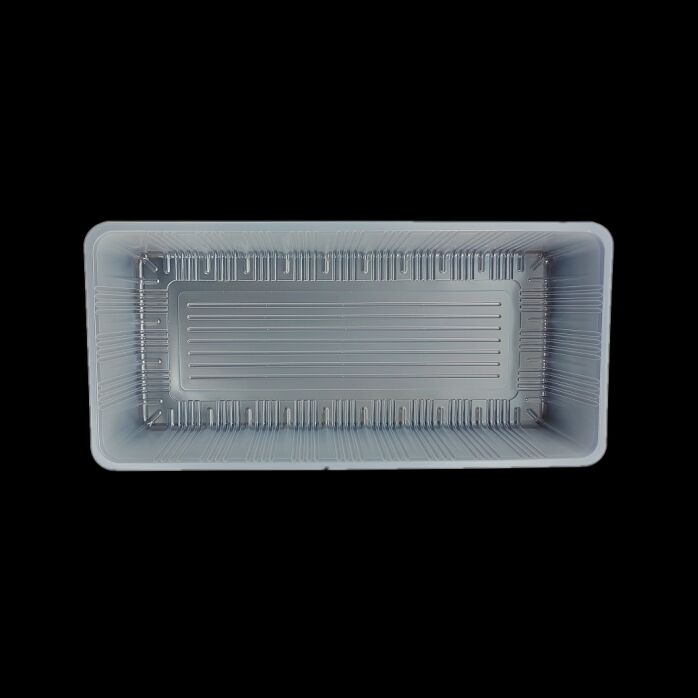

plastic trays for frozen food types

Plastic trays for frozen food have revolutionized the food packaging industry by providing reliable, efficient, and cost-effective solutions for storing and distributing frozen products. These specialized containers are engineered with food-grade materials that maintain structural integrity at extremely low temperatures, typically ranging from -40°F to 0°F. The trays feature precise dimensional stability, ensuring consistent stacking and storage optimization in commercial freezers. Modern frozen food trays incorporate advanced polymer technology that prevents cracking and breaking during temperature fluctuations, while special surface treatments enhance food release properties. The design typically includes reinforced corners and edges to protect contents during transportation and handling. These trays come in various sizes and configurations to accommodate different portion sizes and food types, from single-serve meals to family-size portions. The materials used are FDA-approved and meet international food safety standards, offering excellent barrier properties against moisture and oxygen. Many versions feature compartmentalized designs, allowing for separate storage of different food components within the same meal. The manufacturing process ensures uniform wall thickness and smooth surfaces, facilitating easy cleaning and reducing the risk of bacterial growth.