Modern food packaging operations demand precise sealing solutions that maximize efficiency while maintaining product integrity. Roll over wrap trays have emerged as a revolutionary packaging technology that transforms how manufacturers approach modified atmosphere packaging and vacuum sealing processes. These specialized containers feature innovative design elements that significantly improve sealing performance compared to traditional rigid packaging alternatives. The unique construction of these trays allows for superior conformability during the sealing process, resulting in enhanced barrier properties and extended shelf life for packaged products. Food manufacturers across various sectors are increasingly adopting this technology to meet growing consumer demands for freshness and quality.

Advanced Design Features of Roll Over Wrap Packaging

Flexible Sidewall Technology

The cornerstone of roll over wrap trays lies in their flexible sidewall construction that adapts dynamically during the sealing process. Unlike conventional rigid containers, these trays feature specially engineered sidewalls that compress and conform to the product contours when vacuum is applied. This adaptive behavior eliminates air pockets and creates more intimate contact between the packaging film and the product surface. The flexible design also accommodates varying product heights and irregular shapes without compromising seal integrity. Manufacturing facilities report significant improvements in packaging consistency when transitioning from traditional trays to these advanced systems.

The engineering behind flexible sidewalls involves precise material selection and wall thickness optimization. Manufacturers utilize multi-layer polymer compositions that provide the ideal balance between flexibility and structural integrity. These materials must withstand repeated compression cycles while maintaining their original shape characteristics. Temperature resistance is another critical factor, as the sidewalls must perform consistently across varying processing environments. Quality control protocols ensure each tray meets stringent flexibility standards before entering production lines.

Enhanced Flange Design

Roll over wrap trays incorporate sophisticated flange designs that significantly improve sealing reliability and efficiency. The flange area features precision-molded surfaces with optimized contact zones that promote uniform heat distribution during thermal sealing operations. Advanced surface treatments enhance the adhesion properties between the tray flange and sealing films. Micro-textured patterns on the sealing surface create multiple contact points that distribute sealing pressure evenly across the entire perimeter. This design innovation reduces the likelihood of seal defects and minimizes the occurrence of channel leaks that can compromise package integrity.

The geometric specifications of the flange area undergo extensive testing to determine optimal sealing parameters. Engineers analyze factors such as contact pressure distribution, heat transfer coefficients, and material deformation characteristics during the sealing cycle. Computer modeling techniques help predict sealing performance under various operating conditions. Manufacturing tolerances for flange dimensions are maintained within extremely tight specifications to ensure consistent sealing results across high-volume production runs.

Sealing Process Optimization

Modified Atmosphere Packaging Integration

Roll over wrap trays excel in modified atmosphere packaging applications where precise gas composition control is essential for product preservation. The flexible sidewall design creates superior evacuation characteristics that enable more complete removal of residual oxygen from the package headspace. During the gas flushing phase, the conforming sidewalls minimize dead spaces where unwanted gases might accumulate. This enhanced evacuation capability allows for more accurate final gas compositions and improved packaging consistency. Food processors utilizing these trays report significant reductions in oxygen residuals compared to conventional packaging systems.

The integration process involves sophisticated gas handling equipment that coordinates with the tray sealing mechanisms. Precision gas injection systems deliver specific gas mixtures at controlled flow rates and pressures. Sensors monitor gas composition throughout the packaging cycle to ensure compliance with predetermined specifications. The roll over wrap trays respond predictably to vacuum and gas injection cycles, enabling automated systems to achieve consistent results across extended production periods.

Thermal Sealing Efficiency

The thermal sealing performance of roll over wrap trays surpasses traditional rigid containers through several key mechanisms. The flexible sidewall construction allows for more uniform pressure distribution across the sealing interface, reducing hot spots and cold zones that can lead to incomplete seals. Heat transfer characteristics are optimized through precise material formulations that conduct thermal energy efficiently while preventing overheating. The conforming nature of the trays ensures consistent contact between sealing surfaces even when dealing with products of varying dimensions or irregular shapes.

Temperature control systems work in conjunction with the tray design to achieve optimal sealing conditions. Programmable heating elements provide precise temperature profiles tailored to specific film and tray combinations. Real-time monitoring systems track temperature variations across the sealing zone and automatically adjust parameters to maintain consistent sealing quality. The thermal mass characteristics of roll over wrap trays enable rapid heating and cooling cycles that increase throughput while maintaining seal integrity.

Industrial Applications and Benefits

Meat and Poultry Processing

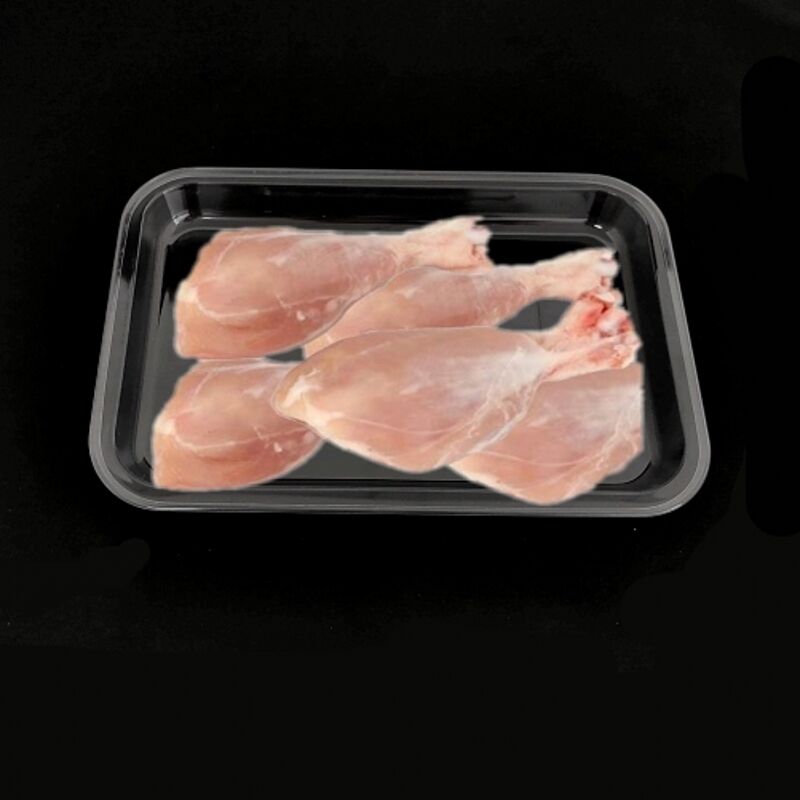

Meat processing facilities have embraced roll over wrap trays as a superior solution for packaging fresh and processed meat products. The conforming sidewalls accommodate the irregular shapes of meat cuts while maintaining intimate contact that prevents moisture migration and oxidation. Extended shelf life performance exceeds industry standards when these trays are properly implemented in controlled atmosphere environments. The enhanced sealing capabilities reduce purge loss and maintain product appearance throughout the distribution cycle. Quality assurance protocols demonstrate consistent packaging performance across diverse product categories including steaks, roasts, ground meat, and processed items.

Processing line integration requires careful coordination between packaging equipment and tray specifications. Conveyor systems must accommodate the flexible nature of the trays while maintaining precise positioning during sealing operations. Automated handling systems recognize the unique characteristics of roll over wrap trays and adjust manipulation parameters accordingly. Training programs ensure operators understand the specific requirements for achieving optimal sealing results with these advanced packaging systems.

Prepared Food Manufacturing

Prepared food manufacturers leverage roll over wrap trays to package complex multi-component meals that require extended shelf life and visual appeal. The conforming sidewalls adapt to varying product heights and contours found in prepared entrees, side dishes, and combination meals. Sauce retention properties are enhanced through superior sealing characteristics that prevent leakage during distribution and storage. The flexible design accommodates thermal processing requirements including retort sterilization and microwave heating applications. Consumer acceptance rates increase significantly when products are packaged in these advanced tray systems due to improved product presentation and extended freshness.

Manufacturing efficiency gains result from reduced packaging line downtime and fewer rejected packages due to sealing defects. Roll over wrap trays demonstrate consistent performance across varying production speeds and environmental conditions. Quality control metrics show substantial improvements in seal strength consistency and barrier property maintenance. Cost analysis indicates favorable return on investment through reduced product waste and extended distribution capabilities.

Performance Metrics and Quality Standards

Seal Strength Characteristics

Roll over wrap trays consistently achieve superior seal strength values compared to conventional rigid packaging alternatives. Laboratory testing protocols measure peel strength, burst strength, and creep resistance under standardized conditions. The flexible sidewall design contributes to more uniform stress distribution across seal interfaces, resulting in higher average seal strength values and reduced variability between samples. Industry standard test methods including ASTM F88 and F1140 demonstrate the enhanced performance characteristics of these advanced packaging systems.

Statistical process control methods track seal strength performance across production runs to identify trends and optimize sealing parameters. Control charts monitor key variables including seal width, uniformity, and consistency over time. Correlation analysis reveals relationships between tray design parameters and final seal performance metrics. These data-driven approaches enable continuous improvement initiatives that maximize packaging efficiency and product quality.

Barrier Property Enhancement

The enhanced sealing efficiency of roll over wrap trays translates directly into superior barrier properties for packaged products. Oxygen transmission rates decrease significantly compared to conventional packaging due to improved seal integrity and reduced micro-leakage pathways. Water vapor transmission characteristics also benefit from the enhanced sealing performance, particularly important for products requiring moisture control. Gas chromatography analysis confirms reduced permeation rates across multiple barrier properties when products are packaged in these advanced tray systems.

Accelerated aging studies demonstrate the long-term stability of barrier properties maintained through superior sealing performance. Environmental stress testing including temperature cycling, humidity exposure, and mechanical stress evaluation confirm the durability of packages sealed in roll over wrap trays. Comparative studies with traditional rigid containers consistently show improved barrier maintenance over extended storage periods.

Implementation Considerations

Equipment Requirements

Successful implementation of roll over wrap trays requires careful consideration of packaging equipment compatibility and modification requirements. Existing sealing machines may require adjustments to accommodate the flexible nature of these trays and optimize sealing parameters. Vacuum systems must provide adequate evacuation rates to fully utilize the conforming capabilities of the sidewalls. Heating elements and temperature control systems require calibration to achieve optimal thermal sealing conditions specific to roll over wrap tray materials.

Training requirements include operator education on the unique characteristics of roll over wrap trays and proper handling procedures. Maintenance protocols must address the specific needs of equipment modified to handle these advanced packaging systems. Technical support from tray manufacturers helps ensure smooth transition periods and optimal performance achievement. Investment analysis should consider both equipment modification costs and long-term efficiency gains from improved packaging performance.

Cost-Benefit Analysis

Economic evaluation of roll over wrap trays reveals compelling advantages through multiple cost reduction mechanisms and efficiency improvements. Material costs per package may be slightly higher than conventional alternatives, but these increases are typically offset by reduced waste, extended shelf life, and improved product quality. Production efficiency gains result from fewer packaging line interruptions due to sealing failures and reduced quality control rejection rates. Distribution cost savings accrue through extended shelf life capabilities that reduce product spoilage throughout the supply chain.

Return on investment calculations must consider both direct cost impacts and indirect benefits including brand protection, consumer satisfaction, and market differentiation opportunities. Sensitivity analysis helps identify key variables that influence economic performance and guides optimization strategies. Long-term financial projections typically demonstrate positive returns within reasonable payback periods when all cost and benefit factors are properly evaluated.

FAQ

What makes roll over wrap trays more efficient than traditional rigid packaging

Roll over wrap trays achieve superior sealing efficiency through their flexible sidewall design that conforms to product contours during the packaging process. This conforming action eliminates air pockets and creates more intimate contact between the packaging film and product surface, resulting in better evacuation characteristics and enhanced seal integrity. The flexible construction also enables more uniform pressure distribution across sealing interfaces, reducing the likelihood of seal defects and improving overall packaging consistency compared to rigid alternatives.

How do these trays improve modified atmosphere packaging results

The conforming sidewalls of roll over wrap trays enable more complete evacuation of residual oxygen during the gas flushing phase of modified atmosphere packaging. The flexible design minimizes dead spaces where unwanted gases might accumulate, allowing for more accurate final gas compositions. This enhanced evacuation capability results in improved packaging consistency and better preservation of product quality throughout extended shelf life periods.

What equipment modifications are needed to use roll over wrap trays

Existing packaging equipment may require adjustments to optimize sealing parameters for roll over wrap trays, including vacuum system calibration, temperature control modifications, and pressure setting adjustments. The flexible nature of these trays requires careful handling during automated processing, which may necessitate conveyor system modifications or operator training updates. Most standard thermoforming and sealing equipment can be adapted to accommodate these trays with proper parameter optimization and setup procedures.

Are roll over wrap trays cost-effective for high-volume production

Roll over wrap trays typically demonstrate positive return on investment in high-volume applications through reduced packaging waste, improved sealing consistency, and extended product shelf life. While initial material costs may be slightly higher than conventional alternatives, the efficiency gains from fewer rejected packages, reduced production line downtime, and enhanced product quality often offset these increases. The economic benefits become more pronounced in applications requiring extended shelf life or premium product positioning where packaging performance directly impacts profitability.